Interior Motives: the science of designing a colour

How do CMF teams tackle the design of a new interior colour? What are the starting points, and how is a material mastered for sign-off? Nick Hull investigates the approach of two brands in contrasting segments to find out more

“There are very different processes and timings across design fields,” says David Hopwood, CMF design chief at Mahindra Advanced Design Europe (MADE). “We start by telling a story, creating a philosophy to understand that vehicle and the intended persona. It’s important to understand the capability of various materials and work closely with suppliers. Also, to let the design language speak for itself. There should be an honesty to it. A recycled material need not hide that characteristic.”

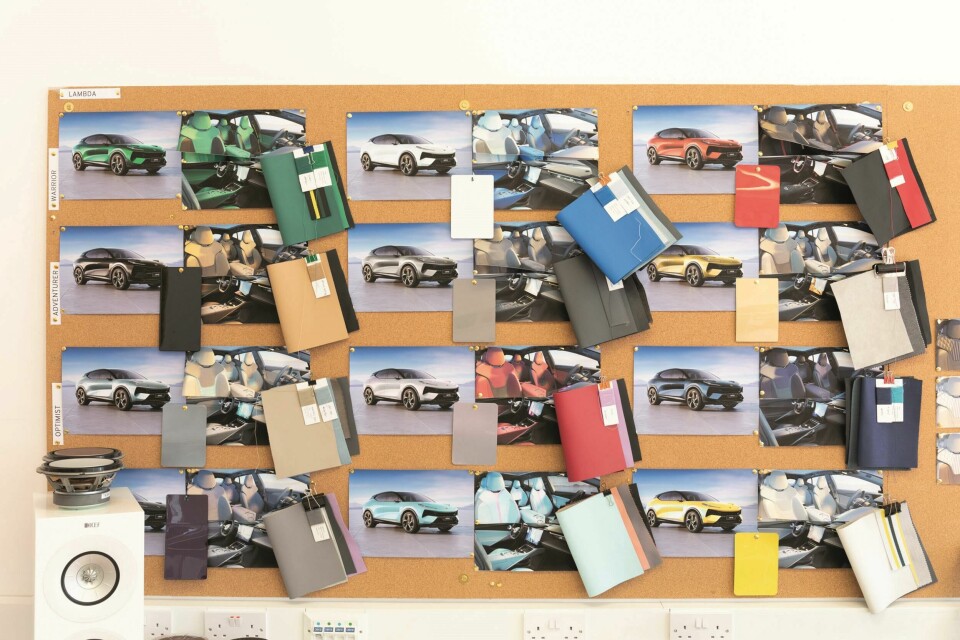

“We take inspiration from non-automotive sources such as art, fashion, furniture, architecture and nature,” adds Marie Camille-Lecoq, head of CMF and sustainability at Lotus. “After that we move to design and material selection to develop the colour. Next, we need to look at the proportion of colour within the car and lastly, where that colour is applied. Leather, plastic, paint, textiles – they will all react differently to the colour because the pigment will react differently with the material itself.”

The timescale for material development differs greatly. For example, Mahindra has a very efficient team in India, says Hopwood. “We can get initial samples from suppliers in a few weeks,” he explains. “It might take a few months to get something we’re happy to present to senior management and 10-20 tries until we’re happy with the colour on a flat sample. Then we’ll try it on a 3D surface to see how it looks as a next step.”

The development of plastics takes a bit longer, Lotus’ Camille-Lecoq notes. “It depends on the complexity of the colour and pigments used. If it’s a neutral colour the implementation can be a bit faster, but generally it’s six to 12 months.” Like Hopwood, Camille-Lecoq has support staff in Asia, with two CMF designers in China to check the materials and samples: “They’re our eyes on the ground to check that the quality and design intent is protected in the product.”

The workflow process on mastering materials and various test specs differs across companies. Typical specifications include tests for abrasion, heat ageing, flammability and light fastness. “Sun creams used to be particularly tricky for many plastics,” says Mahindra’s Hopwood. “So we have to think about the robustness of the application: is it for an instrument panel or door cladding? Reflections and UV fastness will be critical on an IP top pad, but less so for a B-pillar. It’s important to spend time on tactility. Grains can hide a level of wear and tear and also imperfections. Especially with plastics, the customer will touch and feel the material. It’s important to get it right, so people don’t comment on it [negatively].”

Both designers mention that black colours are easier to develop, whereas a more specific chromatic colour will require multiple loops. “First you need to reach the colour that you really like. That will take time,” says Camille-Lecoq. “Afterwards the issue will be to ensure the consistency of the colour. When it is applied on different materials you may need to adjust it yet again. Or when that colour goes to testing, the pigment might change, for example regarding UV stability. All those aspects have an impact on timing. The main issue for us is the consistency and durability of that colour, that’s where we need to be careful.”

CMF is deeper than many people imagine. It isn’t just about pretty colours

Lastly, how has the workflow changed for CMF teams? Hopwood highlights trend sources such as Colourhive and WGSN, as well as attending various industry shows and collating findings from there. “But increasingly,” he says, “we try to do it ourselves rather than rely on outside sources, so we’re not too influenced by others. We’ll reference architecture and furniture too.” Camille-Lecoq agrees, suggesting that CMF teams today need to find their own sources.

“If I ask my own team, they don’t look at the same things, they follow different blogs and influencers and have their own ways to research,” she explains. “They may see a similar trend when they come back from their research, but it’s arrived at from different sources. Some are into cars, others go to exhibitions in London and others are more focused on fashion.

“Another designer is passionate that CMF is more interesting and a bit deeper than many people imagine about what’s going on in the tech world, AI and new innovations. They all come with different sources. I think that makes the CMF area a bit more interesting and also a bit deeper than many people imagine. It isn’t just about pretty colours.”

And what of the role of digital software within the colour, materials and finish design world? “VRED appeared about ten years ago and digital tools help us to go a bit faster, but we still need real samples,” Camille-Lecoq says.

“You can reduce the time it takes, but at the end you always need the mastering and testing because there’s a big difference from what you see on screen and the reality. “Over the years our job has become more complex. We are looking at materials beyond where they are now, not only from an acceptability point of view but also in terms of technology, what they bring to customers and how we can embed them into the materials. I think it’s a good time to be part of design, we are more central now.”

Camille-Lecoq concludes that adjacent interior and exterior designers frequently come to the CMF team for advice on what they can use, and ideally what can be done in a new, different way: “It’s nice to see how it’s shifted, how they interact with CMF now. It’s no longer just considered as being pretty. It’s about how we can influence customer wellbeing and how we build cars.”.