Exploring paint trends

The intersection between chemistry, materials and design

Misty Yeomans, colour styling manager, Americas at PPG, gives her take on the main trends around automotive paint and colour

Car Design News has been taking a closer look at paint and finish this month, with conversations reaching beyond OEM design teams and a little deeper into the supply chain.

We learned in our previous interview with AkzoNobel that paint has become a means for differentiation, not only from brand-to-brand but also at a consumer level. Personalisation seems to be a key word in this corner of the industry, and the modern chemistries are allowing for some interesting solutions.

In our next supplier feature, it is Misty Yeomans, colour styling manager, Americas at PPG, who shares some insight into the world of paint creation and its impact on design.

Car Design News: How has conventional automotive paint developed as a product over the years?

MY: Automotive paint has evolved dramatically from the early days of single-colour finishes like the black paint used on the Model T. Today’s coatings are multi-layered systems designed not only for aesthetics but also for durability, environmental compliance and performance.

CDN: What is the basic structure of modern automotive paint?

MY: It typically includes a pretreatment layer, electrocoat (e-coat), primer, basecoat (colour), and clearcoat. Innovations have introduced waterborne technologies, low-VOC formulations and advanced finishes like matte, metallic and pearlescent effects – each tailored to meet OEM standards and consumer expectations.

As the industry has matured, lightweight and mixed-metal substrates have increasingly been used in modern vehicles, and PPG has responded with advanced coating technologies that enhance adhesion, corrosion resistance and sustainability.

Concept car projects are always a highlight for us — they’re fun

CDN: Do you have any notable examples?

MY: PPG pioneered the Electrocoat (e-coat) and Waterborne compact process for decorative layers - two innovations that have become industry benchmarks. The Electrocoat layer provides uniform corrosion protection across complex vehicle geometries, while the Waterborne compact process reduces environmental impact by minimising VOC emissions and streamlining production. These technologies not only improve vehicle longevity but also support OEMs in meeting stringent environmental and performance standards.

We’ve also come a long way from the Model T colour variety — black was the only option — and are proud of our Colour Design and Styling Capabilities. Each year, PPG’s Global Colour Styling Team provides annual trend reports and consumer insights to its automotive manufacturing customers. These forecasts help OEM designers style colours that will be desirable for years to come.

CDN: What are the key considerations when it comes to developing a new automotive paint for mass production?

Misty Yeomans: There are quite a few. Durability and resistance to UV, corrosion, chemicals and weathering; colour consistency and a uniform appearance across different substrates and production batches; environmental compliance, meeting global regulations on VOCs and hazardous materials; process compatibility and the integration with OEM manufacturing lines and curing processes. Then there is cost-efficiency, balancing performance with production and application costs, and finally design intent: aligning with a brand’s visual identity and CMF strategy.

CDN: By comparison, do one-off projects allow greater freedom?

MY: Yes, one-off projects such as concept cars present interesting and fun opportunities to explore colours and effects that may be new to the market or outside the normal scope of design specifications. It also loosens the reins on technology and application.

For example, some effects and colour behaviour achieved through hand-spray application is simply not feasible in typical OEM production line application and/or specifications. Concept car projects are always a highlight for us — they’re fun, creatively rewarding, and allow us to explore bold, new directions in colour and effects. These vehicles are typically prepared using a manual, manufacture-like approach, including hand-spraying techniques that enable us to achieve unique visual outcomes. However, this process is fundamentally different from the automated serial production lines used by OEMs, meaning the designs created for concept cars are often not directly transferable to mass production.

A tinted clear coat adds a layer of depth and richness

That’s why we approach these projects with both enthusiasm and responsibility. While we enjoy supporting these one-off initiatives, we’re mindful of not creating unrealistic expectations for consumers. Our goal is to develop styling concepts that are not only distinctive and desirable but also technically feasible for large-scale manufacturing, ensuring that innovation can truly reach the market.

CDN: How closely do you work with car designers, or those involved in design?

MY: PPG’s styling, technical, commercial and engineering teams work together and closely with their OEM customers to reach the CMF targets set by the designers. This close collaboration ensures not only that the creative and brand vision is achieved, but the coating itself meets all industry and brand requirements, technical specifications and production line application needs for a seamless end-to-end experience. Automotive colour development from concept to application can be more than 28 months and span multiple teams on both the OEM and supplier sides so trust, collaboration and communication are important.

CDN: How does the “finish” of the paint influence the final colour itself?

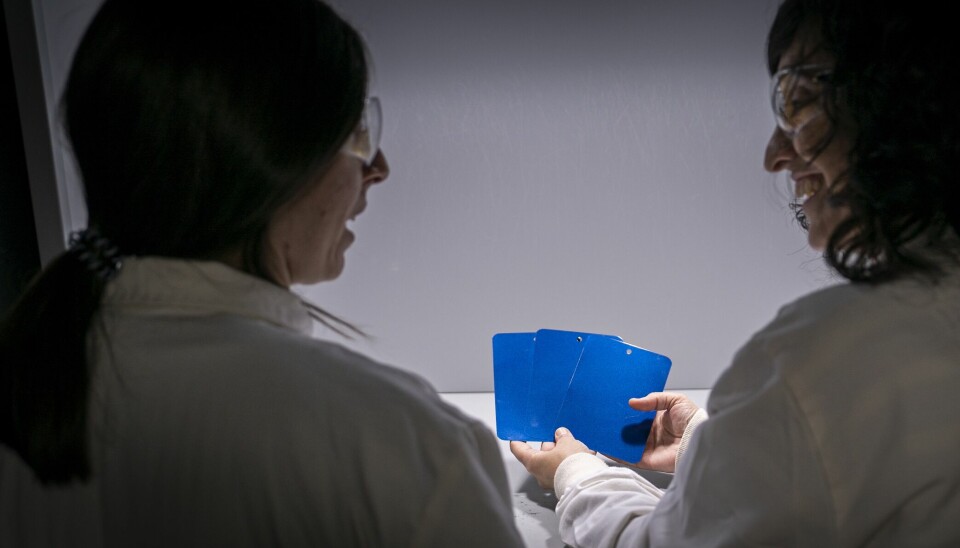

MY: The finish plays a crucial role in how a colour is perceived. Gloss and matte (lower sheen) finishes in automotive styling can dramatically alter the visual impact of a colour. For example, a deep blue in high gloss may appear vibrant and sleek, while the same pigment in matte could feel more subdued and sophisticated.

Finish affects light reflection, depth and even the tactile impression of the surface, making it a key design element alongside colour. It does not alter the actual pigment(s) in the paint but does alter the visual impact: lower sheen/matte finishes have been growing in popularity in the automotive segment. Depending on the sheen level and OEM specifications, a matte finish may require special care, however. For example, a matte finish is not recommended for car washes and care must be taken when buffing the vehicle to avoid increasing the sheen in that area.

Another way to achieve a distinctive and dynamic colour effect is through the use of a tinted clear coat. Unlike a traditional transparent clear coat, a tinted clear adds a layer of depth and richness that enhances the base colour, creating a visually striking and eye-catching finish. This technique gives the vehicle a unique character and presence on the road, setting it apart from standard finishes with a more immersive and dimensional appearance.

CDN: What kind of attention do you pay to colour trends?

MY: We are always monitoring trends and provide annual reports, as well as custom reports to our customers. The PPG Global Forecasting Team meets annually and is composed of colour experts from throughout the organisation. This team supports our customers across all of PPG’s business units. Its annual report forecasts trends in CMF for the next several years and also includes consumer behaviour insights and additional research to provide a well-rounded and industry-leading forecast to help guide customers’ work.

CDN: How can colour influence the driver or customer’s perception of the car?

MY: Colour influences emotional response, brand perception and the owner’s personality. Bright colours like red or yellow can evoke energy and sportiness, while neutral tones like silver or grey can suggest sophistication and reliability. Studies show that colour can affect purchasing decisions, and colour, effect and finish preferences can vary by region and demographic.

Collaboration with suppliers like PPG is essential to translate design intent

PPG works closely with its OEM CMF design customers to create a colour and finish that aligns with the style, type and brand of car to achieve a comprehensive aesthetic throughout the vehicle. Colour shifts, effects and the behaviour of the colour as it “travels” over the various shapes of the vehicle are all opportunities to create a unique look that may resonate with consumers to express personality and style.

CDN: Are there any misconceptions or myths around automotive paint?

MY: One common misconception is that all automotive paints are essentially the same. In reality, they’re highly engineered multi-layer systems designed to meet rigorous performance standards, from durability and corrosion resistance to environmental compliance and aesthetic appeal.

Another myth is that colour is purely cosmetic. While it certainly plays a role in design, colour and finish can significantly influence a vehicle’s resale value and brand perception.

And finally, automotive paint isn’t applied like house paint. The process is far more complex, involving robotic spraying systems, multi-stage layering, curing ovens and precise environmental controls to ensure consistency and quality across every vehicle.

CDN: What does it take to be a paint expert, and is this kind of expertise already embedded in the carmakers' CMF teams?

MY: Being a paint expert requires deep knowledge of chemistry, materials science, application processes and design trends. It’s a multidisciplinary role that bridges engineering and aesthetics.

Many CMF teams at OEMs have strong expertise in colour and finish, but collaboration with suppliers like PPG is essential to translate design intent into scalable, high-performance coatings. In some cases, deeper technical understanding of paint behaviour under manufacturing conditions is a gap that suppliers can help fill.