“I don’t want only the design leaders presenting to me – I banned PowerPoint, full stop”

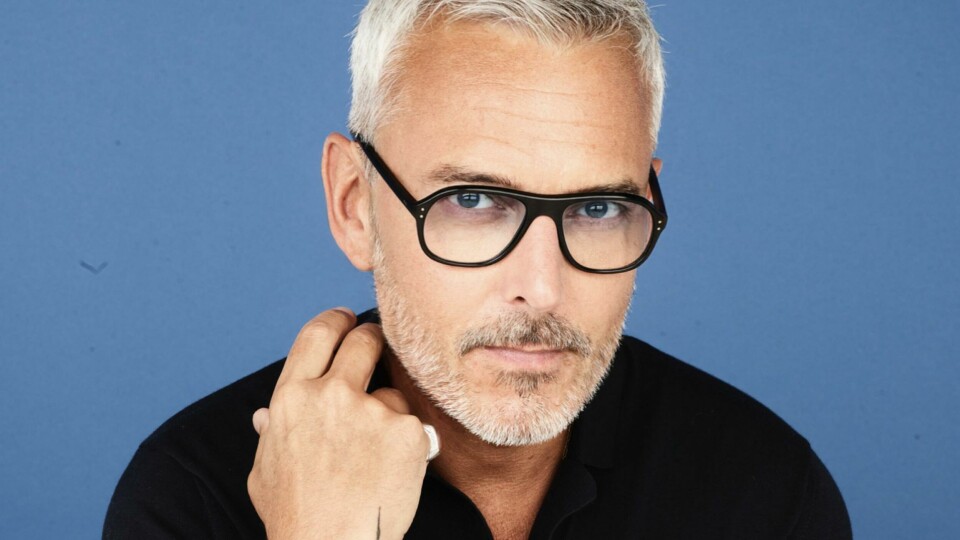

Car Design News paid a visit to Gothenburg to meet with Jeremy Offer, Lisa Reeves and Nick Gronenthal who form part of Volvo’s design leadership team

There is a culture shift underway at Volvo’s design department led by new boss Jeremy Offer who is borrowing from his previous experience at more agile companies to instil a less siloed approach to design. As this restructure beds in, all eyes will be on the storied Swedish brand to see what that will mean in practice. One thing is for sure – it will not involve Powerpoint.

Car Design News: My first question was going to be about any restructuring you’ve done, because I’m sure you have your feet fairly fully under the table now.

Jeremy Offer: In the classic sort of design methodology, I spent the first six to eight months in that kind of discovery phase. We’re very much now in the definition phase, and we will be soon moving into the delivery phase. That really is the crux of it – understanding the organisation, understanding where design fits and how we can improve communications. Some areas of the business still feel quite siloed to us, so how can we create a much more collaborative working spirit. I think design was probably the main silo.

CDN: Why was design in a silo?

JO: Because of the secrecy with which we operate. And I mean that within the context of the company. Also, at Volvo, design is geographically siloed from the rest of the business as well, so you end up with these ‘ta dah’ moments of revealing the design.

I want to bake in a much more collaborative spirit, where design has a voice at much earlier stages of the R&D and product definition process. Understanding design as a business tool and not just as a styling exercise.

There is this idea of creating a much more holistic design organisation and bringing the core disciplines of car design closer together. Because even within design I was seeing silos. We have exterior, interior, CMF, car UX, visualisation, design ops, all of these separate functions. Where it makes sense we will aggregate some of these into what we’re calling a one-team culture, which Nick and I will be rolling out to the team.

Nick’s joined as head of automotive design, and it’s exactly that. It’s to create this one-team culture out of a number of siloed operations, which loosely, together, form car design. By knitting it together as a stronger, defined organisation within design, it creates this much more holistic working, collaborative spirit together. It also means that the reporting lines are simplified as well.

I don’t want to just hear the same design managers or design leaders presenting to me. In fact, I banned PowerPoint, full stop

Nick Gronenthal: I think if you zoom out one layer further, this is where Jeremy and I really see eye-to-eye, just from our backgrounds being very similar and dissimilar at the same time. We both came from the start-up world very recently.

One of the big strengths of those kinds of companies is they’re miniature organisations trying to be larger organisations. And in design you really work right next to everybody, and collaboration is a necessity.

When we say things get a little siloed in a large organisation like here, we recognise how we can learn from where we came from [at those start-ups]. If you look at all the design departments put together, I think it puts us as an organisation at a great advantage, giving us a much more holistic vision of design – where interior’s not just thinking about the interior, exterior’s not just thinking about exterior, etc.

We’re selling a product, and that is a result of a collective effort.

CDN: What does that mean in practice?

JO: The idea of creating a “speak-up” culture where all of our designers are empowered to have an opinion. That was so critical for me. I don’t want to just hear the same design managers or design leaders presenting to me. In fact, I banned PowerPoint, full stop.

CDN: Good for you.

JO: And all our reviews, if we do need to do them digitally, then they’re on Miro. That is just a window – a point in time. We can just jump on the Miro board of a particular design review and see the work as it’s happening. So the time spent doing presentations, frankly, I don’t want to know. We’re all visually literate designers that can identify a great idea from a thumbnail sketch, so I don’t want people to spend a huge amount of time creating elaborate visuals just to present to me.

I want to feel like we are part of a team and can move around freely, expressing opinions and hearing opinions from all of the designers in whatever discipline they’re in. Without them spending two weeks prepping for a presentation to the head of design where everyone’s sitting in a dark room in silence while I pass judgement on a PowerPoint presentation.

CDN: Was that a culture shock to elements of the business?

JO: I knew that was generally how the automotive industry was set up, and I think Volvo has recognised it doesn’t want that. In this new era, design is more than just exterior, interior and CMF. The largest design team is probably UX, and I don’t mean just digital UX but also physical UX. The overall user experience is so important when we talk about the future of the automotive industry.

We don’t want a sterile experience, we still want that poetic involvement with the driving experience

When one of the primary experiences of the ICE world is removed – the connection to the engine, to the gear change – there is potentially a more sterile environment as cars become more like devices. A key thing we want to bring back is the poetry of the automotive experience.

CDN: How do you do that?

JO: By enabling designers to think about the future of the overall experience, rather than just what it looks like. The emotional response that you have to a beautifully-designed physical dial or a touchscreen icon, or whatever it is. These are the things that we want to kind of bring out, and why we term it poetry.

There’s a fantastic quote from Dieter Rams, one of my personal heroes: limit everything to essential, but don’t remove the poetry. This idea of what I call rational simplicity, simplifying where we need without creating a sterile experience.

CDN: One of the questions hovering over you a little bit was that you weren’t necessarily a car guy. Obviously, Nick has that background [Canoo, Faraday Future, VW, Chrysler, BMW Designworks). Was that partly why you brought Nick to Gothenburg?

JO: It wasn’t so much that Nick is a car guy. It’s more that he shared the same values that I do, in terms of how to set up a design organisation. That again goes all the way to the top. That goes to our CEO, Jim Rowan. Jim sees design as being so much more than just the design of the car.

It’s the way that we operate, the way we act and how we build cultures within the organisation. In fact, I’ve literally just stepped out of a presentation where we’re starting to roll out the new vision and principles for the design team, which basically encompass a lot of the things that we’ve just been talking about.

We have become material-led, and when we’re material-led we’re also process-led, and that means R&D

CDN: Can I ask when we might see designs reflecting all this, Jeremy?

JO: As you know, it’s very difficult. You don’t just sort of shut off the taps and go right, one day we’re designing vehicles this way, and the next we’re going to design them this way. It will filter through into all of the new vehicles that are in the current cycle plan.

Lisa Reeves: The industry is transforming and I’d say that how we designed for the last generation is very different to the generation ahead. Jeremy mentioned UX becoming really important, but we also have very ambitious sustainability targets. That means that we’ve become material-led, and when we’re material-led we’re also process-led, and that means R&D.

There’s a lot of reasoning why we need to adapt to be really more holistic from the beginning, and cross-functional with the sustainability elements of the design as well.

JM: This means being involved much earlier in the process, and working much more closely with R&D.

JO: Yes. At a platform level. If you combine the rational way that designers think through problem solving with fantastic engineering, then you have a perfect combination. It’s no longer about throwing things over the wall to each other; it’s about collaborating right at the genesis of a car programme, even at a platform level.

CDN: Working with R&D at a platform level – can you expand a little bit?

JO: We need to be a lot smarter in terms of our material choices. I don’t just mean what we use to cover our seats or IP. I mean the materials that we build our vehicles from, and to look at the sustainability of those raw materials. Whether we are using aluminium, or what polymer of plastic we’re using. Understanding those at a very base platform level. But then, when we get into the core heart of the CMF team work, having that mindset of, as Lisa rightly says, being material first.

We’re not designing forms and shapes and then finding a material that can work with that form. We use the materials that we know are going to imbue us with the sustainability values that we need, and then define the form, based on the processes that we have at our disposal.

The Tier 1 suppliers need to know that there are other suppliers knocking on their doors from China. The lead times with which the industry has historically operated under need to speed up

CDN: Lisa, do you want to jump in on that one as well, because I think it feels quite crucial?

LR: Generally speaking, we’re looking to increase the recycled content of our materials, and also the energy that’s involved in the processing. We have looked at both natural materials that are regrowable using waste crops, and providing those really nice rich textures as well.

On the other side is recycled materials, where we always work with the tonality of the space to create a really nice harmony and balance, especially with the texturing and celebrating those aesthetics at the same time.

CDN: Are you going to have to push the limits of your team, Lisa, beyond what they’ve been used to before?

LR: Absolutely – it’s not a known procedure anymore. You are much more involved with the suppliers, understanding the limitations of the materials in terms of the properties. We go through so much testing, which takes a long lead time, and the interior should be robust with a long lifetime.

But with each process, and with new materials and new properties, you’re adjusting ingredients the whole time to work with that process. Then the shape as well. Sometimes it has a restriction in how deep you could compress it, for example, so it impacts the radii you can achieve. It’s a learning curve for how to execute and work with the form language and also provide the quality and execution for the costs.

CDN: With this comes the challenge of speed of development. Are you going to go faster?

JO: I think the entire industry needs to up its game, and I think that extends out to the supply chain as well. The Tier 1 suppliers need to know that there are other suppliers knocking on their doors from China. The lead times with which it has historically operated under, do need to speed up. The design process, the R&D process, the software engineering process within the automotive industry also needs to shine a lens on itself as well.

On the materials side, this really elevates CMF to be a real key player in the car design process. No longer is it at the end of the process when we are choosing the colours and finishes. We are absolutely reliant on these materials to create new expressions of premium and luxury. Obviously, space and light is something that we can absolutely play with a lot more. But materials are the third part in that trinity.