Interview: Brian Balicki, head of design, Volvo Trucks North America

The interior of the new Volvo VNL truck highlights the crossover (and constrast) between commercial vehicle and passenger car design

Heavy-duty (HD) trucks do not tend to make frequent appearances on Car Design News for obvious reasons, but the latest work from Volvo Trucks North America highlights the parallels with both car exterior and (even more so) in interior design.

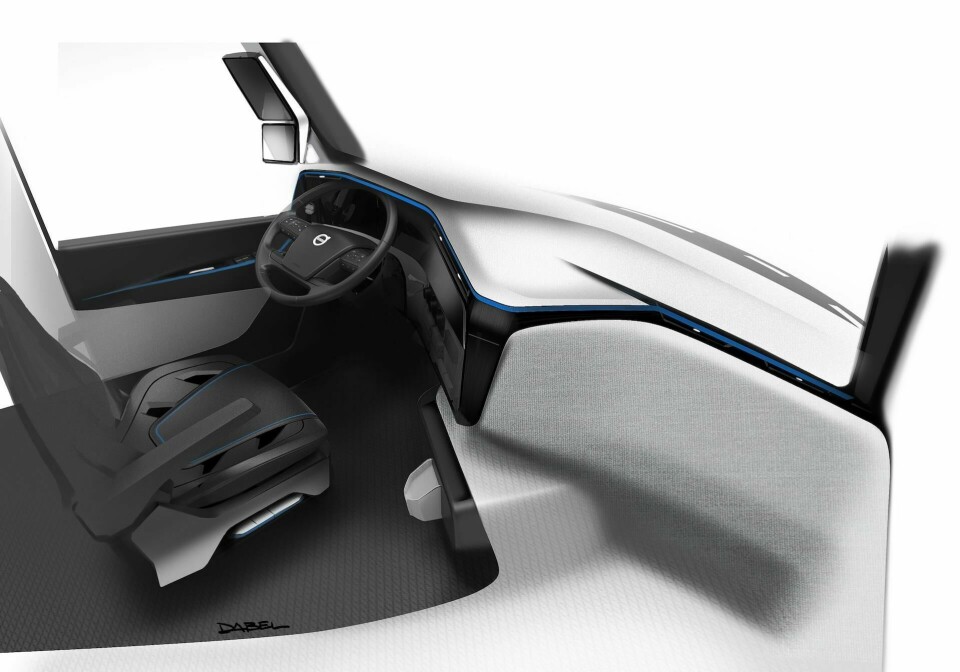

The team led by head of design Brian Balicki took it upon themselves to make the new VNL not only spacious, comfortable and efficient, but to do so with as much style as a big rig can offer. In this interview, Balicki shares the design process behind a Class 8 truck, the challenge of creating an interior that is both workplace and bedroom, and why interior lighting plays such a pivotal role for driver safety and well-being.

Car Design News: You say the new VNL presented a “blank sheet” opportunity for the design team. How so? And does that level of freedom almost present its own challenge?

Brian Balicki: We were given the opportunity to redesign 90% of the vehicle! There were challenges using a ‘blank sheet’ but thankfully we had many knowledgeable stakeholders within our company. They provided critical prerequisites and technical input to apply to the development of the all-new VNL. Influences include the Greenhouse Gas regulations, our new electrical architecture plus feedback and input from drivers and customers.

CDN: Did you draw any inspiration from outside industries – hotels, airlines, restaurants – to help shape the interior?

BB: The products we produce require many unique and clever solutions. Storage, cost and weight are strong factors for Class 8 trucks, so we looked to the recreational vehicle (RV) and marine industries. Attending many of these expos allowed us to not only benchmark space-saving executions, but also research material choice and increased quality. Of course, we also lean on automotive and airline for innovative and trending solutions.

CDN: How much of a step change is this interior design with respect to previous models?

BB: Our drivers and customers have expectations that stem from passenger cars and trucks, so the experience of comfort and technology within their personal vehicles is now expected in our products. We have gone extra lengths to work closely with our suppliers to ensure the level of quality and experience is elevated in the all-new VNL.

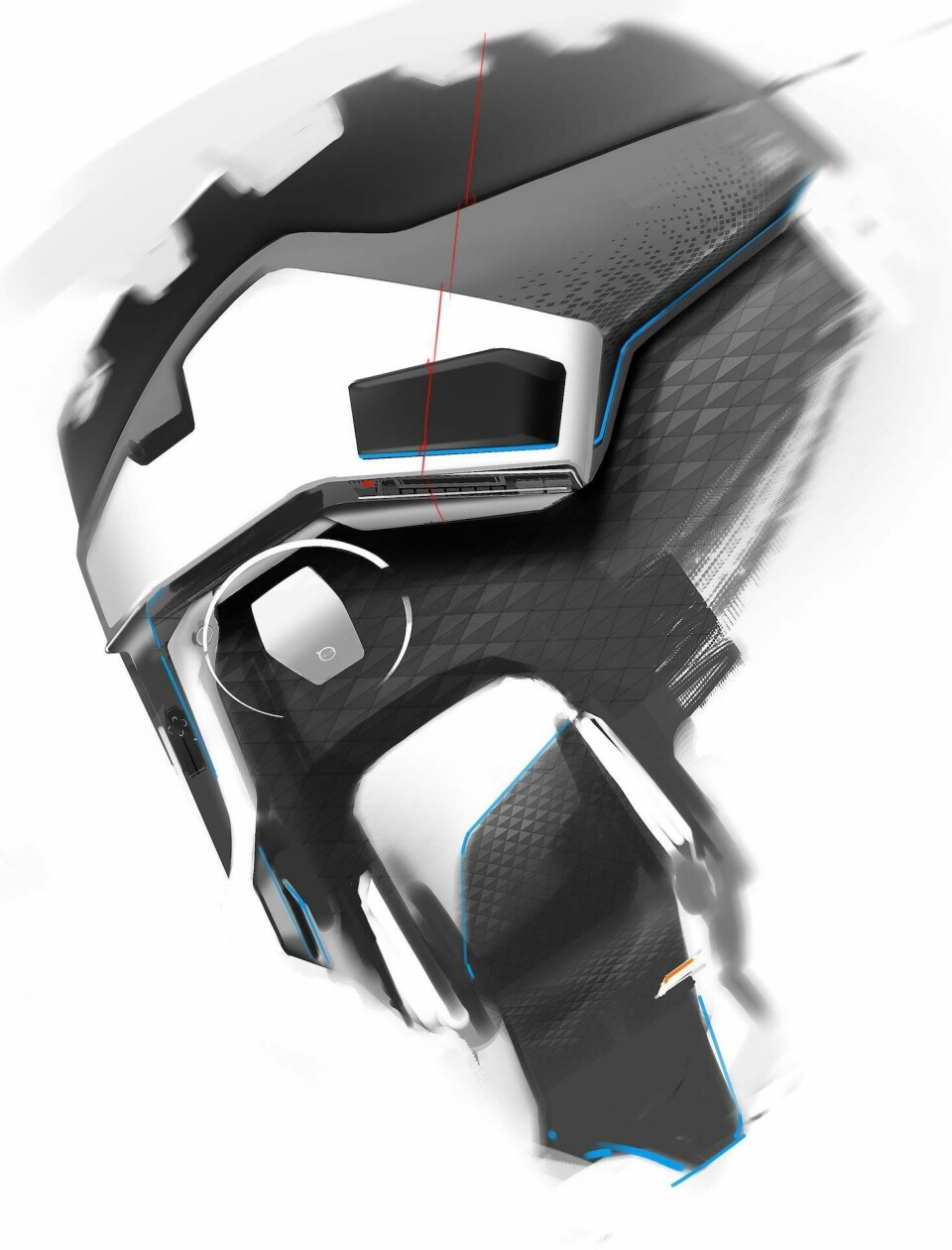

Packaging and ergonomics played a key role in determining the final surface treatment

CDN: What kind of crossover is there with passenger car interior design?

BB: Our driving environment in Class 8 trucks is very similar to a passenger vehicle; raising the level of comfort and safety, and bringing the most modern technologies and features to our users.

However, the living environment is where there are very noticeable differences compared to the back row of a passenger car. Many unique solutions need to be executed in a creative and innovative way to provide proper storage and sleeping amenities, along with ambient and task lighting. It is in this area that we bring influences from marine, RVs and even airline industries. We want our users to feel ‘at home’ away from home, in their own First Class sleeper.

CDN: HD trucks are as functional as they come, but when it comes to creating a sleek, aesthetically-pleasing exterior, does it help that aerodynamics is also a driving force?

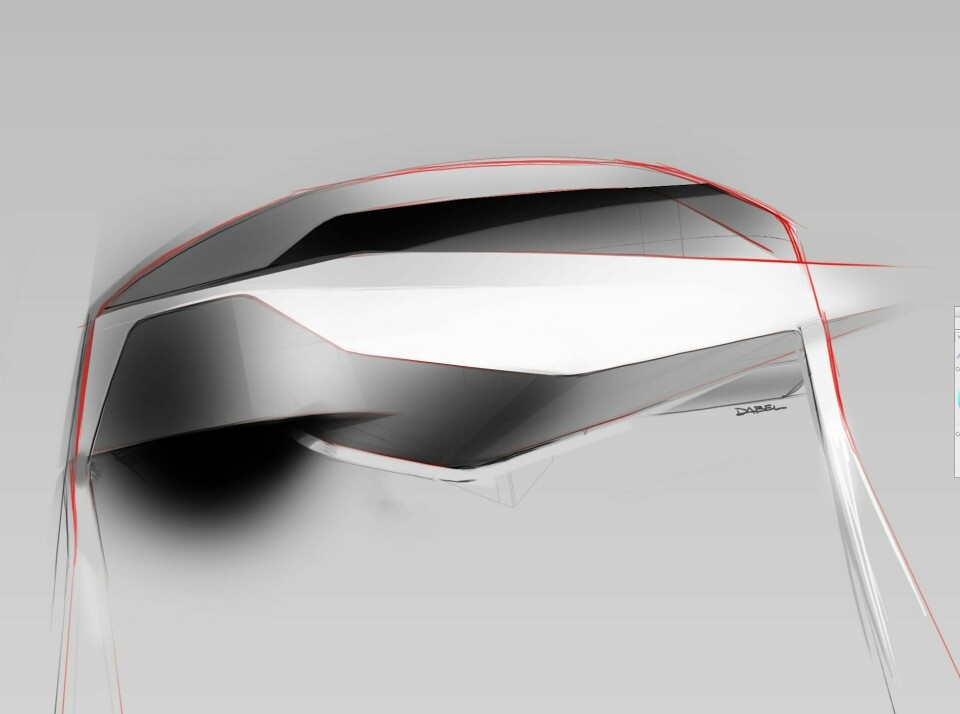

BB: For design, aerodynamics was a very strong driving force in determining the aesthetic look and feel of the all-new VNL. There were numerous meetings, simulations and reviews with our aero team to balance the computational fluid dynamics (CFD) target with Volvo Trucks’ brand message.

CDN: Any particular examples?

BB: The windshield was quite a complicated component to develop and work together with the surrounding elements. Lots of technical input went into the look, fit and finish and function of this very important piece of glass. Packaging and ergonomics played another key role in determining the final surface treatment. Proper storage and sleeper berth is a must for Class 8 trucks and can effect exterior shapes, so both design and engineering should be very proud of what was accomplished in bringing the look of the all-new VNL to life.

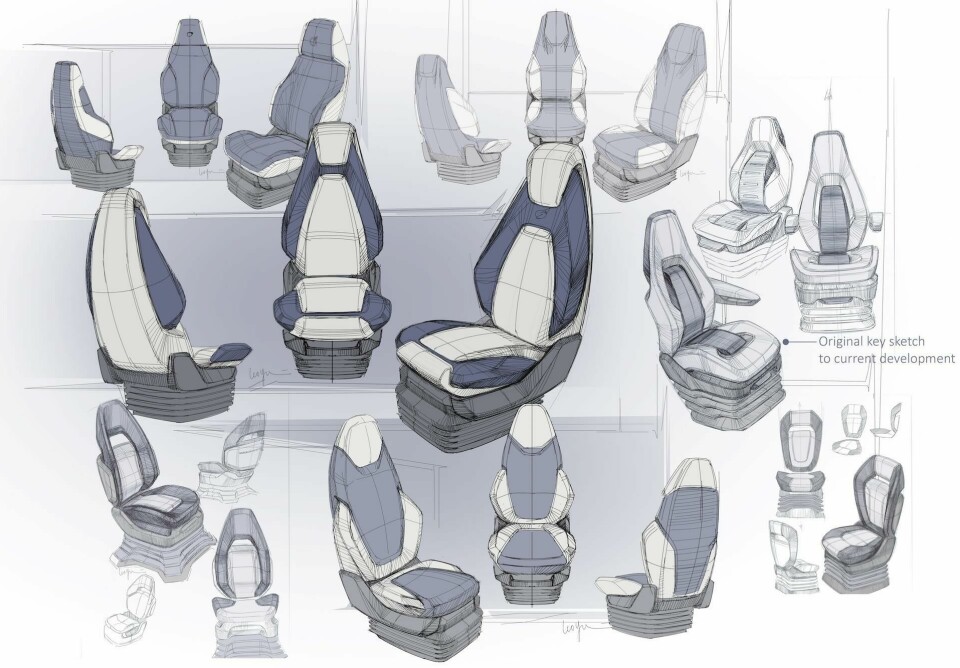

CDN: Can you describe the overall design process – was there a mix of digital and physical models?

BB: While there is a big shift to move to more digital, we still use some traditional processes like hand sketching and clay modelling for development. Newer digital tools like Unreal Engine, Figma and Vizcom are opening fresh and exciting ways for us to explore, design and present concepts and solutions.

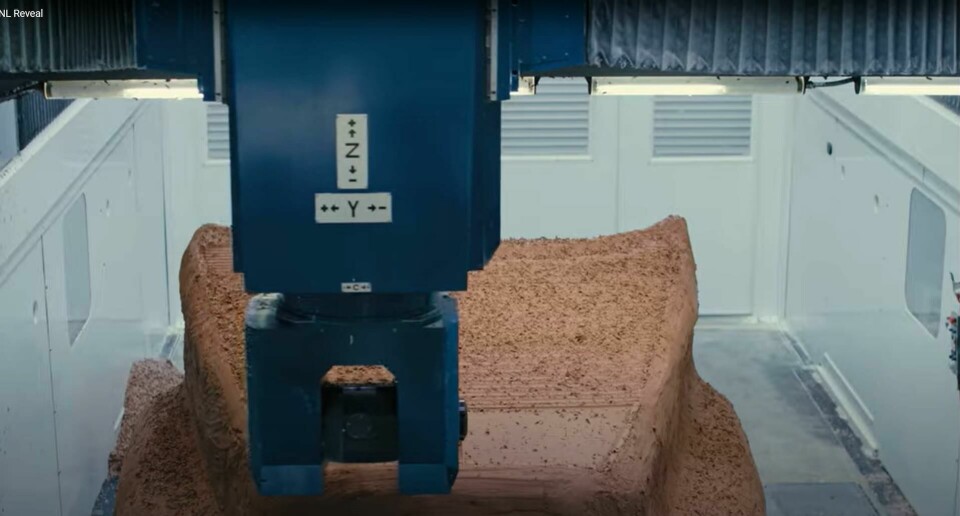

CDN: How much clay are we talking?

BB: When working with a full 1:1 scale, long high-roof sleeper, there can be multiple pallets of clay involved. Each section of the vehicle is broken out into ‘cubes’ that allow us to place on our milling machines for more efficient logistics.

At the same time, our digital tools are getting higher and higher in fidelity, allowing us to reduce some of the physical steps needed to verify and validate. 3D printers have come a long way too and quickly allow us to prove out many smaller components made of many different materials that require quick evaluation or review. Many stakeholders within our organisation participate in reviews either around the clay, a VR/XR station or our Powerwall projector system.

CDN: Unless going “bobtail,” the tractor is usually just a small section of the overall vehicle, which is mostly trailer. How does this influence the design process?

BB: Greenhouse gas regulations are influenced by fuel consumption, which in turn is influenced by aerodynamics and powertrain technology. The exterior surfaces of the tractor and the components installed all need to work together as an orchestra. Our Cab Engineering aero team used CFD to simulate thousands of computations, and together, we were able to achieve form following function while still having a very strong design execution.