Studio tour: Bentley’s evolving Crewe campus

Car Design News was invited for a tour of Bentley’s sprawling campus and to chat with both senior and junior designers

As Car Design News is based in the UK, it is always nice when the opportunity arises to visit a local (ish) design studio. Nestled in an unassuming suburb of Crewe, not too far from Manchester, Bentley’s headquarters retains much of the original site’s pre-war architecture and industrial feel with more modern touches. Pitched roofs atop the main assembly line buildings were created to mimic surrounding houses, disguising the factory from aerial attacks in WW2 (or trying to, at least – it was bombed in 1940).

Our visit began at the swanky dealership set away from the main factory where we are met by returning design director, Robin Page, to dig into the brand’s illustrious history –punctuated by aviation, motorsport, its acquisition by now arch-rival Rolls-Royce, and a shift to high volume production alongside its coachbuilding activities.

Page and his team often visit this heritage centre, tucked away behind closed doors at the back of the dealership, for sources of inspiration but also to stay connected with the brand’s roots. A semi-circle of some astonishing models show how the brand has evolved from battling at the famous Brooklands race circuit to a focus on travelling in supreme comfort (and style).

But as indicated by the worn leather and wood trim sported by many of these early models, craftsmanship has been a constant throughout its history. On our tour of the facility we were greeted not only by mechanics and engineers but also leather experts, wood trim specialists, master polishers and seamstresses with decades of experience.

Given the nature of these vehicles – and their clients – there is a little more freedom to make sure things are done properly at Bentley, and mistakes however small are immediately rectified even if it means starting again. And in many cases, each craftsperson has their own particular set of hand tools, we are told, and their own way of working. Good things come with time, and to paraphrase Bruce Lee: fear not the man that has used 10,000 buffing machines, but he who has used one buffing machine 10,000 times.

But as Page explains, the company is very much moving with the times and what worked a century ago is not necessarily the way forward. Early Bentleys featured covered wheel arches, for example, as car design was engulfed by the streamliner movement. In theory, could we see cues like this return to Bentleys? Don’t bet on it. “We have looked into this actually, but it turns out that it’s not really any more efficient in terms of aerodynamics. Back then it was probably more about having clean surfaces, but we have the right tools today to properly optimise aerodynamics.” Other heritage cues like the leather bonnet straps are also off the table, if you were wondering.

The level of customisation available to buyers is vast not only for exterior finishes but particularly on the inside, with unique embossing, embroidery and to be frank, anything the customer asks for. We learned that clients such as the Shoe Surgeon – an LA-based custom footwear designer – has tattooed his own veneer for IP in a Flying Spur. One buyer even requested her name on the headrest of the driver’s seat, and the word “Boyfriend” on the other. As we move through the building, reams of leather hides (bought directly from an Italian supplier) only underscore the breadth of options available. We are told Mandarin Orange is particularly popular at the moment.

Much of this comes from the work of Maria Mulder and her CMF team, which as we learned on the day is in the process of expanding (a recent hire even joined us for a chat). A series of samples helped to illustrate how products trialled in concept cars often find their way into series production. For example, a naturally-pigmented 70% wool-based fabric used in the EXP 100 GT show car can be seen in the Odyssean Edition of the Bentayga SUV.

We also saw early samples for the Opalite trim used in the Flying Spur Edition 12 (which CDN borrowed for a week) that aims to bring “a little bit of magic to a solid paint colour,” Mulder explains. Conversations with senior interior, exterior, UX and branding designers showed the same kind of care and detail goes into the entire design development.

Indeed, the full design team currently consists of 70 permanent staff, with support from other external design partners. It was a slightly awkward time to be visiting the design team in hindsight, which is currently working out of a temporary space while the new, bespoke studio is in the process of being constructed at the heart of the site; this should be done towards the end of 2024 all going well.

Page says that the new three-storey unit will support the full range of modelling activities, with an atrium that is flooded with natural light at the centre. The current studio is quite compact, but still has space for three models to be developed at a time when using supporting office space elsewhere around the site. “It’s difficult to give exact dimensions,” Page explains.

We regularly partner with British universities

We were also joined by a mix of junior and graduate designers from different fields to get a sense of what it is like to work at Bentley as a young designer. As it turns out, this was something of a surprise for some, but it sheds a good light on their education and training thus far as each came across as laid-back, knowledgeable and passionate.

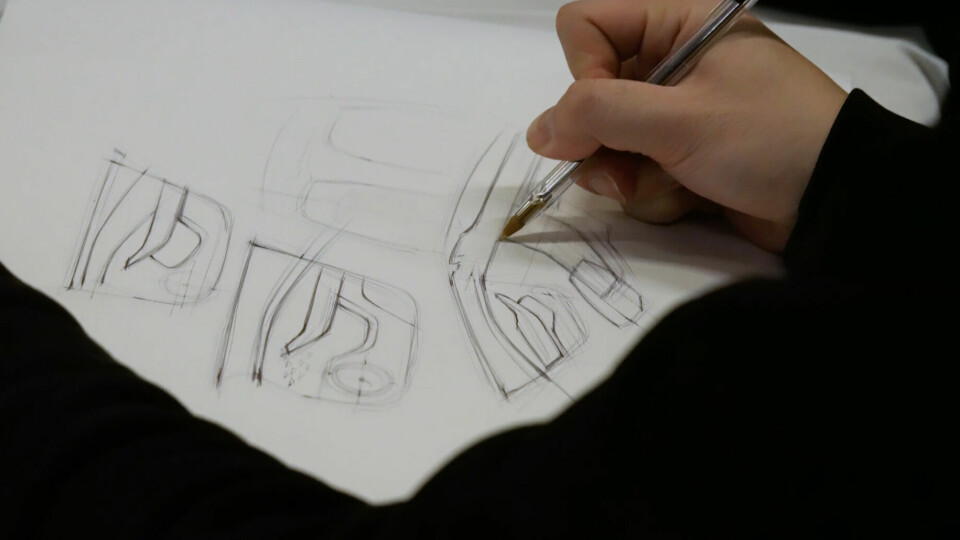

This was a particularly satisfying part of the visit as it showed how the next generation are approaching the task of designing a car. It also showed how there are different pathways into car design beyond the well-trod routes of a Transportation Design BA or MA. One recent graduate from nearby Staffordshire University was brought into the visualisation team for his experience in videogame design, for example. Despite his relative lack of experience, he has been in high demand across all design departments, as has the junior studio engineer who helps to coordinate efforts between design and engineering.

Elsewhere on our roundtable, the exterior and interior designers were clearly passionate about pencil sketching but also digital modelling; and a recent CMF hire explaiined how her experience from the fashion industry should lend itself to the new role at Bentley. Another graduate outlined how her experience as a graphic designer landed her a job, and was experimenting with a new typeface as we chatted. “We regularly partner with British universities,” says Page, not only Staffordshire but others such as the Royal College of Arts in London.

The Bentley facility, or CW1 House as it is known, is steeped in history and still feels very much a traditional way of working today. The factory floor is jolly and the design team is surrounded by inspiration from the brand’s illustrious past – both distant and recent. With Page back at the helm, the task moving forward will be to address evolving consumer trends in parallel with the bread and butter of luxury design.

These are vehicles that will be used not only for prancing outside Harrods – the Bentayga recently won luxury towing car of the year – and there is very much a different kind of customer these days.

From skiing trips and golf days to driving across continents, camping in the desert or hauling goods to a wedding, Page recognises luxury vehicles in general are now being bought as “all-round entertainment devices.” A Bentayga SUV mounted with a roof rack seems to underline the point.