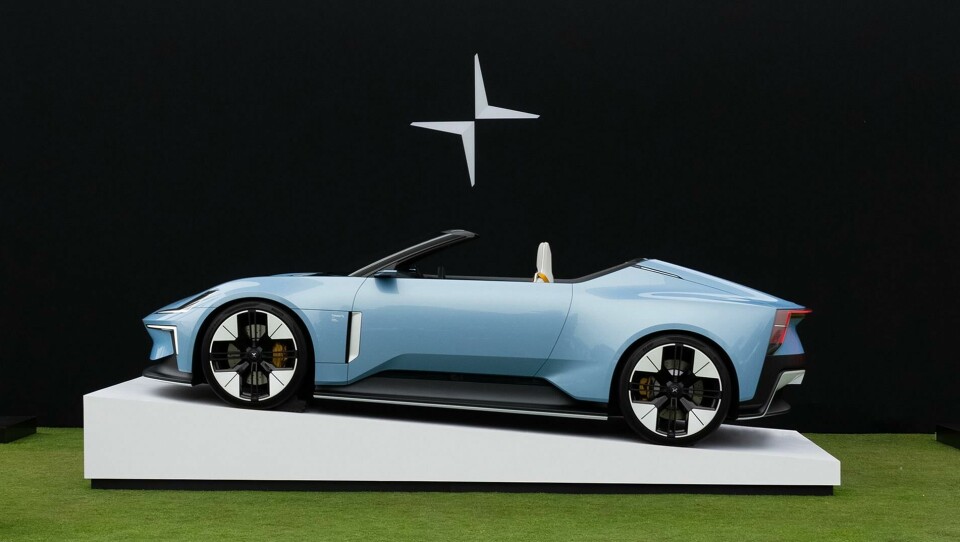

“We make luxury sportscars – the Polestar 5 and 6 will show that”

During a recent visit to Gothenberg, Car Design News stopped by to speak with Polestar design director Maximilian Missoni whose design team has once again claimed the Car Design Review production car of the year award

Polestar recently rejoined the mother ship that is Geely, finally closing the chapter on its origin story as a Volvo spin-off brand. For design director Maximilian Missoni, this is a logical move as the brand to establishes itself as a luxury sportscar manufacturer.

Though the brand and electric vehicles are facing headwinds from a slowdown in demand, one thing that continues to work in its favour is a committment to design and innovation as evidenced by the design team’s Car Design Review 10 production car of the year award in 2023.

Car Design News: There’s a lot of appreciation in the design community for what you’re doing here, but were you surprised the award went to you again?

Maximilian Missoni: You hope that people appreciate what you do, but then it’s always a surprise when it actually happens. It’s very nice – the special thing about this award is that it is the peer group, and it’s all very experienced members of the peer group. So they know quality, that’s what makes it special. There’s different attributes to different awards, but this one is really special because it’s experienced, seasoned members of the design industry.

The strength of Polestar is to plug into the Geely Group’s capabilities with the platforms that are already developed and tune them for higher performance

CDN: What’s next for Polestar?

MM: The 6 is the sportscar short wheelbase version of the 5, so same power, same battery capacity, same battery pack, exactly the same platform. We have the volume products, the SUVs and the 2, which is also a crossover fastback. They are on group platforms. So 2 and 3 on Volvo platforms, and the 4 on the more premium Geely Group platform. That makes total sense, and they’re also built in those factories, together with the other products on these platforms. That’s where we find synergies.

Then 5 and 6 are built in a unique factory that’s specifically built for this architecture, which is this bonded aluminium unibody, suitable for medium volumes, and very stiff, rigid sportscar platforms. That is Polestar’s own platform.

CDN: Where was it developed?

MM: It was developed in England by the team that sits in Coventry. They are experts in aluminium bonding technology. And the beauty of it is that it’s very light and very stiff because of the bonding process. It’s full aluminium. We even developed our own motor for this car, which is more compact and more powerful than the other motors we are using in the SUVs. So it is really to stake that claim and say we are a luxury sportscar manufacturer, and these two cars really prove that point.

CDN: Do you see a time when Polestar will be virtually self-sufficient?

MM: I mean, it depends how far we look forward, but even quite far, I would not think so, because the strength of Polestar is to plug into the Geely Group’s capabilities with the platforms that are already developed, creating top hats on these platforms and tuning them for higher performance. That’s really good, because of economies of scale.

CDN: Of course.

MM: It is the so-called asset-light model that you plug into the existing infrastructure. Then, on the high-end side, to have this exclusive small family of sports cars – the 5 and the 6 at this point – that really then sets us apart, even from the rest of the Geely Group in that luxury performance area.

So I think the two complement each other quite nicely. You couldn’t do a broad family of products on the aluminium bonded architecture because it is a more medium volume, more high-priced situation.

CDN: The new platform, what advantages is that going to give you?

MM: It’s lighter and the 5 is going to have 885 horsepower – so it is going to be light and it’s going to be very powerful.

With the expertise that the British engineers have, they are really good at tuning cars for performance. And we’ve already had that. People that have driven the 5 prototypes were very impressed by the behaviour of the car.

That is definitely one advantage, that you have this very sporty architecture. And then the scalability is really strong. That’s why we have two body styles to start with on this architecture. Because we have a foot garage – that space within the battery pack – the rear passenger can put their feet under it and the seats can be lowered down flat onto the battery.

It is similar to a Taycan, for example, but what we then can do is we can lose that foot garage, keep the same battery pack, the same modules, and create a shorter but equally powerful derivative, which is the 6.

CDN: How closely do you personally get involved with engineering and manufacturing decisions?

MM: Well, two answers to that. In my case it’s a little special, because on the engineering side it’s very similar to other brands. We have an escalation system where lots of decisions are being taken between the designers and the engineers. And then when there can’t be a consensus, it leads to so-called alignment meetings, which I am part of, where the head of engineering and I have a little conversation.

They are very important, because sometimes there is no consensus to be found on the working level, and then we have to escalate, and then everybody has to prepare. It’s like a little mini court case. But only in the rarest of cases do we have to then escalate to the CEO and say, look, we cannot get together here. And normally Peter Allen, who is the head of R&D in the UK, and our respective teams come to good conclusions within that system.

It’s so nice when you get that feedback from people who go through the process every day, every year, and with every model they release, and then you see that they are impressed with your work. It’s a great confirmation that the magic is still there

CDN: Given the size of the team, you must be involved in many facets of the business.

MM: We have this unique setup in our company, with Thomas being the CEO but also having been on the management team at Volvo. Of course, we are a much smaller company, but I am on that level now at Polestar, so I see and hear and am part of many of the very tricky decisions that have to be made when it comes to manufacturing, logistics, sales and marketing… All the shit that can hit the fan, let’s say.

CDN: Do you find it frustrating when you’re getting pulled into conversations like these. Do you ever think, I just want to make a beautiful car?

MM: Sometimes I struggle with having to understand and be involved in everything, because of course, mostly when things escalate to the CEO level it’s about problems that need solving. So that’s always challenging, always complicated.

But on the other hand, I feel so much more rounded as a professional, because I really have that insight. So, I wouldn’t want to miss it.

CDN: And what about the work itself, Max?

MM: It is funny to say, but you never have the pleasure of the ‘wow’ moment in your own work. You can see that with your colleagues. With the other judges in the [Car Design Review] books, you see their work and you go ’how cool is that’. But you never have that with your own work, because it starts as a sketch, it gets changed to a certain degree, then you try to force it back, then it doesn’t work. You go through the whole process, you see it for three, four years, and then when it’s finished, you’re not impressed anymore [because you’re already looking at the next big thing].

But you can be impressed by your colleagues’ work. And that’s why it’s so nice when you get that feedback from people who go through this process every day, every year, and with every model they release, and then you see that they are impressed with your work. It’s a great confirmation that the magic is still there.