Concept Car of the Week: The GM Precept

An innovative concept that emerged from an equally progressive government program, the Precept still has much to teach us two decades later

In 1993, the United States government and the Big Three American car automakers teamed up in a co-operative research program to re-envision the car for the twenty-first century. The alliance was called the Partnership for a New Generation of Vehicles (PNGV), and involved GM, Ford, and Chrysler, along with eight federal agencies, and host of national laboratories, and universities.

The objective of the partnership was to make the typical vehicle more efficient, lessen the environmental impacts of the automobile, and decrease America’s dependency of foreign sources of oil. Affordability, comfort, performance and safety were not to be compromised in the new designs, and where possible, were to be enhanced. The vehicles soon acquired the nickname “Supercars”, although there was some doubt that the effort, which involved so many agencies and organizations, would be able to produce a truly advanced automobile.

At the individual vehicle level, the program looked to create a family sedan the size of the Ford Taurus of the era, capable of seating five and achieving 80mpg (2.9L/100km). It was an audacious goal, some 2.5 to 3 times the fuel mileage of the era. Early on, it was decided that the powertrain would be a diesel/ electric hybrid, though the specifics were left to the individual.

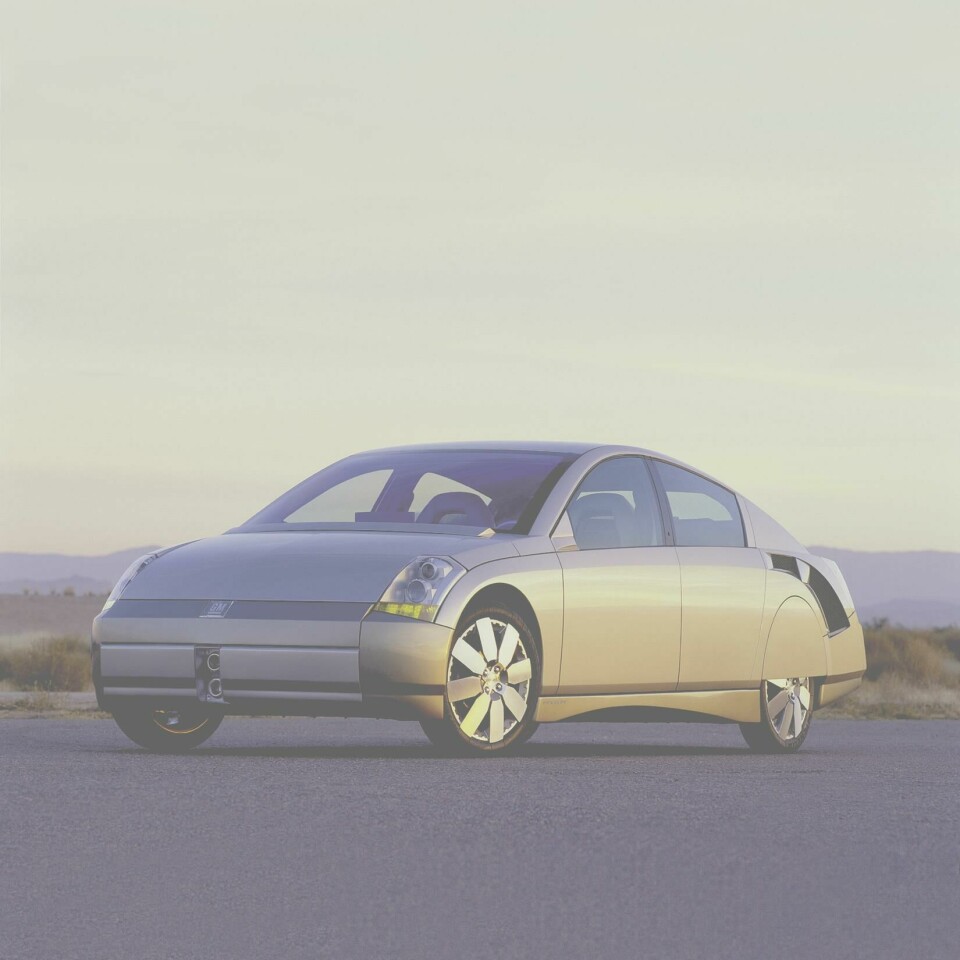

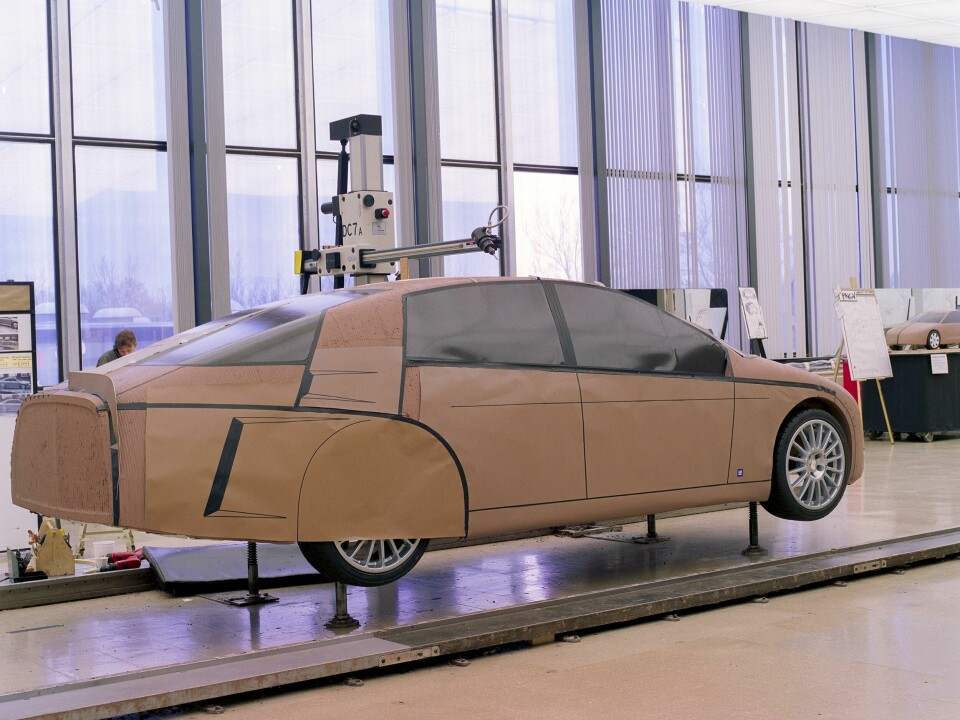

When the prototypes were completed and introduced at the 2000 North American International Auto Show, Ford and Chrysler revealed forgettable variations on the sedans of the time, albeit more aerodynamic and fuel efficient. But General Motors introduced the Precept, a car that was a radical re-thinking of the sedan in styling, architecture, and powertrain. Or perhaps, an update of previous innovative vehicles. The Precept was vaguely reminiscent of the Tucker Torpedo or Tatra 77, sleek aerodynamic (and rear-engined) classics that seem updated for the turn of the millennium.

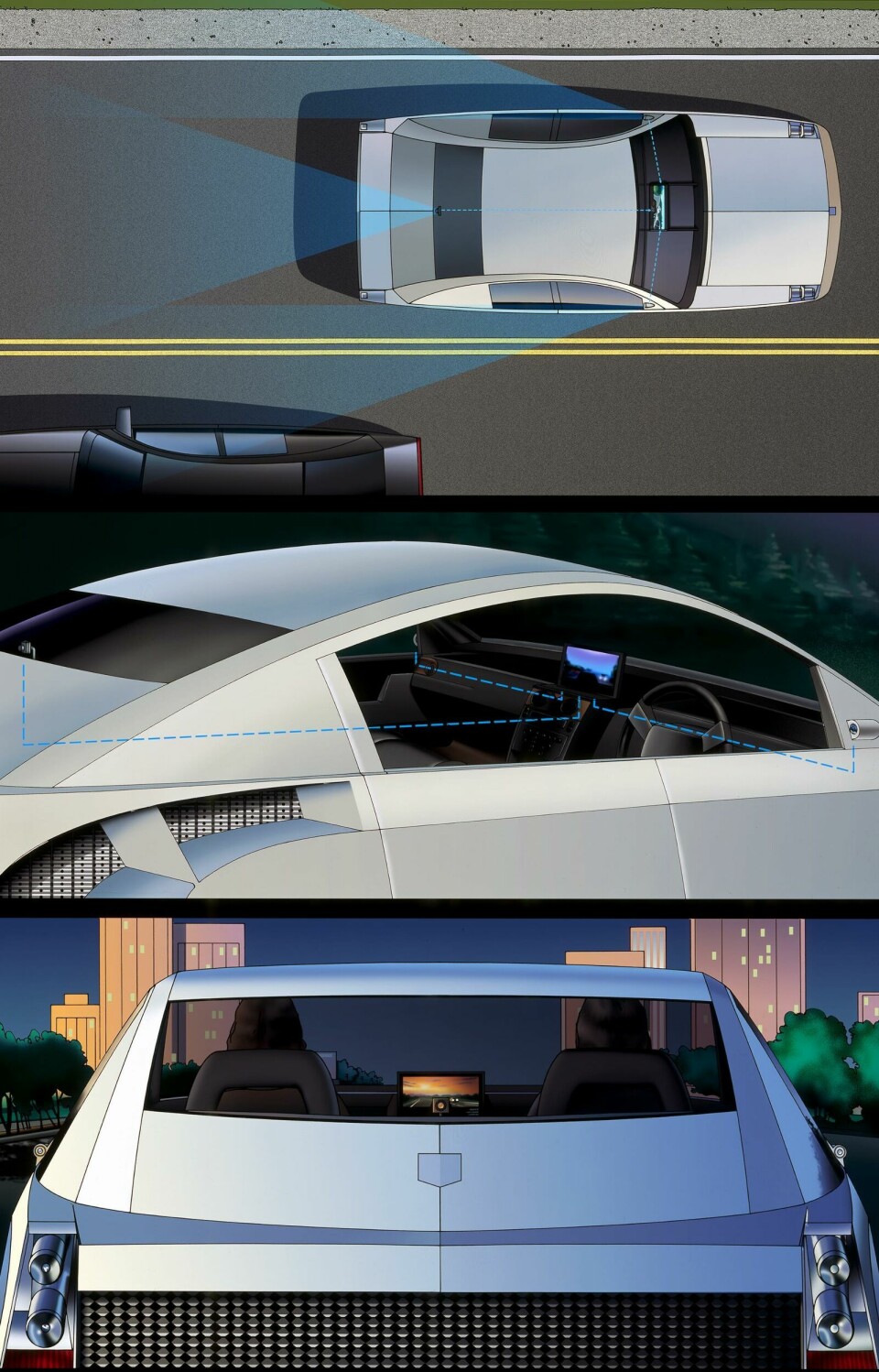

The Precept was rear-engined, with electric motors front and rear. The front aspect of the car displayed a dramatic low nose for a decrease in frontal area. The vault of the roof transitions to a fastback over the diesel drivetrain in the rear. Sides are nearly vertical, with almost no tumblehome. Enormous rear wheel covers, along with the extended rear end, gave the Precept a heavier overall appearance. The openings for the intercoolers at the sides allowed airflow to pass through the radiators and engine compartment without negatively affecting the coefficient of drag. The implementation of a rear- camera system eliminated the need for drag inducing rear-view mirror.

The interior was a composition of simple, rather minimalist, arrangement of lightweight elements. Seats had ultralight construction with a mesh back. An innovative foam covered the IP and many other surfaces. The center stack has actual buttons for many controls, but, at the top, a screen displayed speed, and information and also the views from the various cameras.

The Precept, along with its cousins from Ford and Chrysler, would never see production, though many of their innovations would emerge in vehicles in the following years. Hybrid powertrains, then limited to the Toyota Prius and the Honda Insight, would make major incursions into the market in the following decade. But the diesel engine? Its pollutants overrode any virtues the engine had, and it has now made an exit out of the consumer market here in the States.

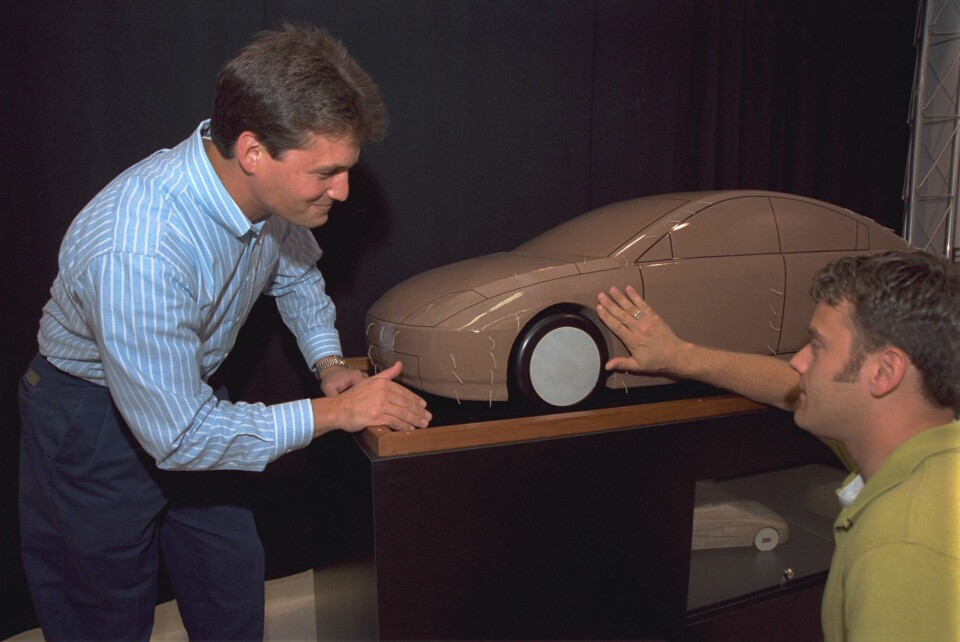

Remarkably, three of the principal designers on the project are still with General Motors. Brian Smith, who is now design director at GM California Advanced Design, Mike Pevovar, who is now exterior design director, and Matt Erdey, who is now design manager at the Seat Design Studio, all gave Car Design News their unique perspectives, as they look back at this innovative project. Their answers to our questions are below, lightly edited:

CDN: Brian, you noted in the recent CDN interview that the aerodynamics played a critical part in the design of the shape of the Precept.

How early in the process was an aerodynamic study undertaken of the proposed design?

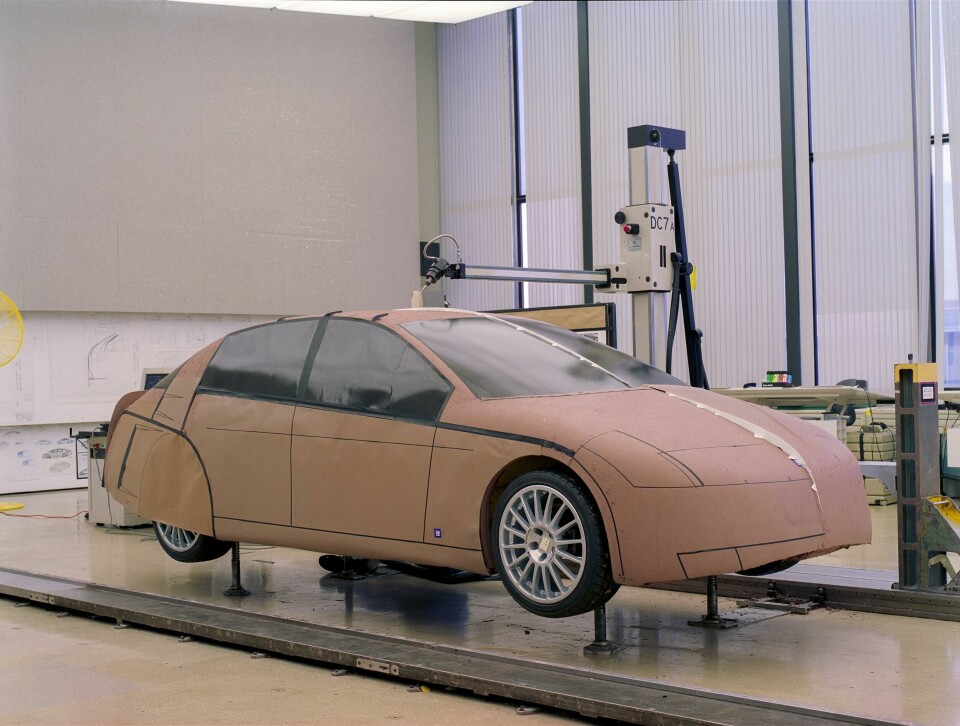

Smith: The aerodynamic development of the car began immediately. There was an engineering shape already underway that we wanted to alter to make more attractive, modern and appropriate. Our design themes were put directly against the “engineering model” in 1/3 scale in the wind tunnel with the hope that we could achieve very close to the same drag with our adjusted shape. It actually outperformed the engineering model, straight out of the studio with a .180 CD before we even touched it.

Pevovar: At the time, hard edges and creases weren’t commonly associated with successful aerodynamics shapes. However, sharply creased exteriors were coming into fashion. We wanted to challenge the notion that both great aero and crisp surfacing couldn’t exist together – they could actually support each other. Throughout the process of sketching and developing scale models, we worked with the GM aerodynamicists to understand general aero rules of thumb.

Through unique application of those general rules, we creatively explored how we could strategically take advantage of the situation to invent something new. One of the greatest things I remember… while different camps and opinions formed at the start of the project about the appropriate shapes/proportions to achieve this lofty goal, everyone excitedly galvanized once it was clear we were on to something. Instantly, one team formed around a common direction and we didn’t look back.

CDN: Was the drivetrain determined by the shape of the car, or was the shape of the car determined by a decision about the drivetrain?

Smith:The shape of the car was determined by the wind tunnel and the rear-mounted heat exchangers for the rear-mounted diesel engine. The approach of an ICE engine in the back with all cooling flow coming through the rear quarters and exhausted into the wake was novel. It provided an almost completely neutral cooling flow relative to drag. Front motor compartments with airflow typically cause .040-.050 CD drag increase. The rear overhang was of course long to package the heat exchangers in this way but it provided a drag-neutral cooling flow.

Pevovar:The shape of the car drove aerodynamics as it had the potential to exponentially contribute to achieving the 80mpg target. The shape came first. The engine placement supported the aerodynamic goal as Brian stated. The long rear overhang that packaged the heat exchangers also helped contribute to a lower drag number through a better aerodynamic proportion/aspect ratio.

CDN: What was the design philosophy behind the design of the interior? Any details that stand out as you look back?

Erdey: Simplicity and lightness was the key philosophy. We utilised lightweight materials and tried to show off the appearance of those materials. One of those materials was a special EPP foam that had unique properties, it was energy absorbing, lightweight, structurally strong with thermal and acoustic insulating properties. This material was used on the IP, doors, center console, headliner, and package shelf. If the area was in an area of high wear, we wrapped the surface in a material to help protect it from scuffs.

It challenged the status quo regarding how a successful aerodynamic car could look and be shaped while still being a functionally spacious automobile for 5

The top of the IP had covered storage, this replaced the heavy traditional glovebox storage a traditional vehicle normally has. At the top of the IP, mounted in the middle was a large laptop. This screen displayed not only the speed and range, but also displayed live video from the side/rear view cameras.

The center stack housed the pushbutton transmission selector (PRNDL), along with the pushbutton start and HVAC controls. There was a multifunction switch that helped control the laptop mounted on the top of the IP.

The roof of the vehicle housed a special antenna made from copper strands, rather than covering it with a traditional heavy headliner, we exposed parts of it and displayed the unique material appearance.

To create the ultra-light front seats, we powder coated the steel and aluminum frame since these would be exposed. We covered the frame with light weight foam in the areas where the occupant contacted the frame. For the middle of the seat, we stretched a special automotive grade mesh material that could handle the sun’s strong UV rays.

CDN: What do you think is the lasting legacy of the Precept?

Smith: I think it shows that a reasonably packaged five passenger vehicle can achieve stunning levels of aerodynamic performance with an attention to detail of every surface. It comes at somewhat of a cost though – covered rear wheels for instance (since we over-achieved on drag we wanted to remove them but got vetoed by engineering) and square corners with long quarters, slab sides. We also proved that an aerodynamic vehicle need not be a jellybean. The aerodynamicists on the team suggested that their “rule book” had been thrown out on this design and it worked anyway.

Pevovar: I love the fact that it challenged the status quo regarding how a successful aerodynamic car could look and be shaped while still being a functionally spacious automobile for 5. It’s not just and aero speed form with wheels. It worked. After it was released, I also loved reading quotes in magazines stating how it wasn’t possible. That “aero” cars aren’t shaped like that. In my eyes, that doubt, that disbelief, was proof we had created something new.

Erdey: We challenged the status quo on everything and in the end, a very cool and unique vehicle was created.