Flashback: Michelin Vision Tire (2017)

For this edition of our recently revived ‘Flashback’ feature, we take a look at an advanced tire/wheel concept by Michelin that may be a game-changer

“Let’s not reinvent the wheel” is a common refrain in the business world, but for Michelin, that was exactly the task they set for themselves as they looked to the future of the tire.

The brief was simple: ”Imagine an object that symbolised the mobility of the future, that was packed converging technologies, and offered an ultra-high level of environmental performance, in accordance with the R&D Group’s strategy and Michelin’s values.”

Creating an eco-friendly, high-tech wheel/tire combination was the goal, and as the project developed, four goals emerged:

1) Develop an organic tire from bio-sourced, biodegradable materials

2) A “rechargeable” tire created with 3D printing, according the level of wear and mobility needs

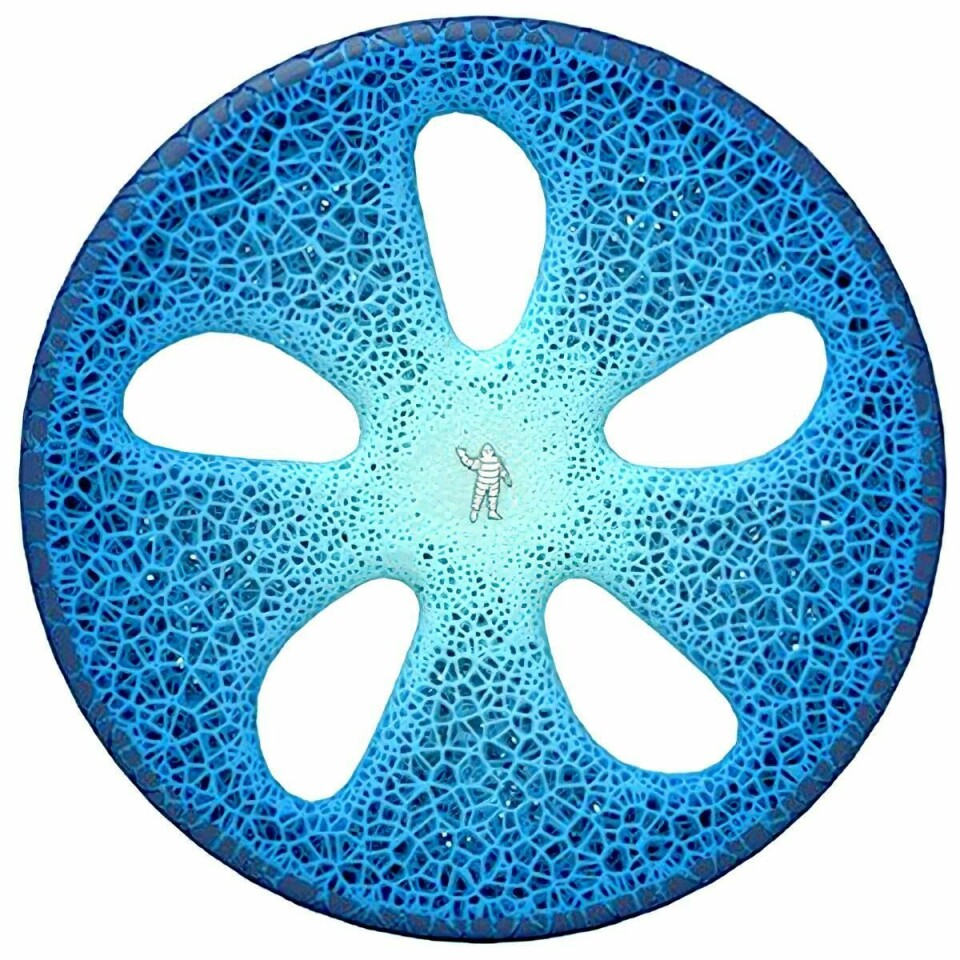

3) An airless tire thanks to its interior architecture

4) A connected tire

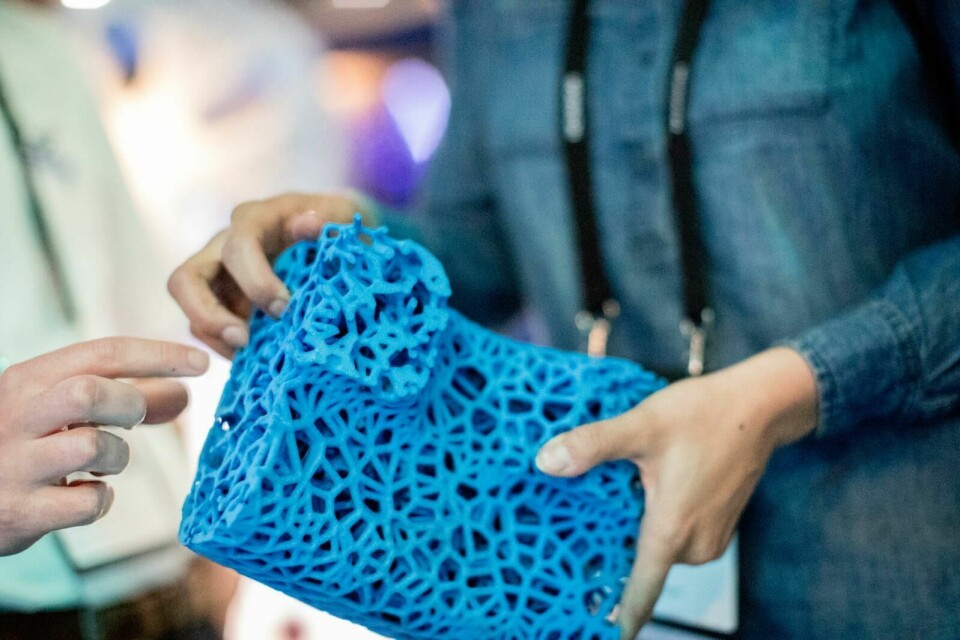

The result was the Vision Tire that is airless, relying on the organic, cellular, lattice-like interior architecture of the wheel to give it support. With the aid of 3D printers it is possible to use just the right amount of rubber on the tires, making for an efficient us of materials. The tread can be recharged as needed, whether for long distance, rugged terrain, or inclement weather.

The Vision is equipped with various sensors that send condition updates, and predictive maintenance schedules to an app on the driver’s mobile phone or vehicle touchscreen.

The Vision was introduced at the Movin’ On summit in 2017, and received a great deal of interest, though many thought the technologies still needed some maturity before being brought to market.

In 2019 Michelin followed up the Vision concept with the UPTIS system (Unique Puncture-proof Tire System) prototype, which has a more convention look, but still incorporates the same innovative ideas about 3D printing, “recharge-ability” and airless technology.

The Uptis had an aluminum wheel core and a flexible load-bearing structure made from glass fibre reinforced plastic (GFRP). The tread can be “recharged” using a 3D printer, and could be available to print for individual preferences and even optimized for local geographical or weather conditions. Like the Vision, sensors are embedded in the tire to update the driver on the Uptis condition.

The aesthetics of the Vision might be the wrong statement for a performance car, where wheels and tires are totems of performance and power. But the Vision might be perfect for smaller city cars or economy cars, where a certain amount of ‘Sponge-Bob’ cuteness fits the overall aesthetic and performance criteria.

The technologies employed in both the Vision and Uptis are still in development, but show enormous promise. Integrated with advanced suspension systems, we may see a total tire/wheel integration, and a revolution in handling and performance. It may yet take another decade or more, but will probably be worth the wait.

Photos courtesy of Michelin and Jimmy Hamelin