Gamechanger: the BMW i3

A radical departure from what had gone before, the i3 set BMW on the path to electrification via a collaborative, though not always harmonious, relationship between the German OEMs design and engineering teams. Mark Smyth charts the story of this gamechanging car

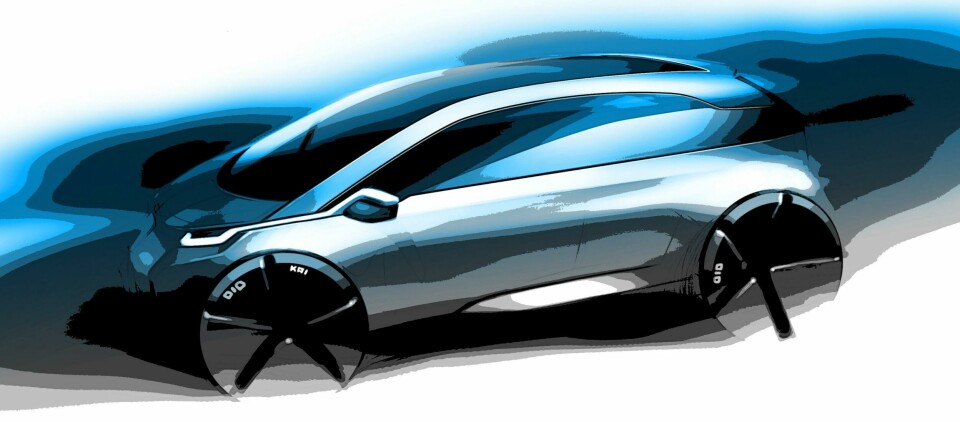

We’ve all been excited by a concept car and then thought, “it’s never going to go into production like that”. Perhaps you’ve designed a few knowing full well that the end result will be toned down dramatically from the sketch that resides on your studio wall. All too often the vision and the eventual reality are very different.

Then there’s the BMW i3. BMW gave us clues with the Megacity concept but let’s be honest, most of us imagined the technology would be transferred into a body more in keeping with the brand’s existing design, possibly into a 1 Series or the Mini. Even if it was to become a new model, surely the world wasn’t ready for a BMW that looked like that.

In 2011 the i3 concept made its debut and we were shocked to see that it still looked radically different, not just to any other BMW but to any other car. Was BMW really about to have its Audi A2 moment? Was it really going to take such a big risk? Surely not.

But BMW did and in 2013 the i3 made its debut in production form. It polarised opinion immediately and now in 2022 it has reached the end of the road. It’s not been a big seller for Munich, with over 250,000 sold globally and speculation that BMW lost a substantial amount of money on it, but few can argue that it’s quirky design, very clever engineering, impressive sustainability credentials and of course, pioneering electrification, make it a real automotive icon.

“It might have been a bit too much for some people, but it has set the path and the mindset for BMW and our willingness to take steps forward”

We jumped at the chance to spend a bit of time in an i3S to become reacquainted with the unique characteristics of the i3, but we wanted the real inside track on how it came about. Who better to fill us in on all the details than BMW i design boss, Kai Langer, who together with Richard Kim designed the little Beemer under the tenure of then BMW’s head of i design Benoît Jacob. It’s a story of fascinating influences including curious neighbours and Segway scooters. It’s about the quest for natural materials that wouldn’t start to smell and a relationship with the engineering team that went from isolated silos to unusual teamwork. From the first sketch to the concept and then the production model, the development of the i3 was an incredible journey, but as BMW today continues to expand its electric i range, was the i3 way ahead of its time?

“Personally, and if you ask people within the company, it was just right at the time,” Langer told Car Design News. “It might have been a bit too much for some people, but it has set the path and the mindset for BMW and our willingness to take steps forward. Everything that we found out during that time, all the mistakes that we made, we don’t have to make them again, while other companies are. It was ahead of its time, but we wanted to make that step. It was to say we have to tackle the future and we’re better prepared for all today’s and tomorrow’s challenges because we made the pioneering groundwork with the i3.”

That work showcases both design and engineering and Langer says that both departments worked closely together rather than one taking the lead. There was talk of simply making it an electric 3 Series, but he says everyone wanted to make something distinctly different, that didn’t step away entirely from the BMW form language but showcased BMW’s intentions with a bold statement. The i3 definitely did that, but how did it begin?

“We started very early with the idea that we have to do a mega city vehicle and then we identified what it should be and that its urban surrounding meant it needed to be a certain size; small, but still offering space for four people to be comfortable,” he says.

Engineers created A-pillars, roof frames and other structural components that Langer says he and his team just couldn’t work with

The team then began looking at the technology, which arrived in the form of BMWs Life-Drive architecture. Having settled on that, it was time to look at how to package it.

“We debated if we should go the traditional way, make a car look like a car as people have known it for 100 years,” says Langer. “Should we play with the same toolbox that we’ve seen for decades for smaller cars, or should we go full steam and invent all the technology and develop the tooling and everything it needed.” They went full steam and quickly got to work on the design, which became an unusual collaboration between design and engineering.

“When it comes to inspiration, we looked at how people feel in design environments,” he says. “I can remember that we had a look at loft apartments in New York with a lounge chair in front of a concrete wall, the combination of raw, authentic materials with premium product and design. That was the inspiration we took through the whole car.”

This became a big part of the design, but it also posed a number of challenges. A sustainable material was chosen for the interior, but Langer says that when it got wet it started to rot and so solutions had to be found. BMW had also never used carbon fibre so extensively in a production model and he says it caused a great deal of head scratching.

They quickly found that while carbon fibre is a fantastic lightweight material, where it was great in one area, it wasn’t so great in others. Engineers created A-pillars, roof frames and other structural components that Langer says he and his team just couldn’t work with. Then they decided to go and see the engineering department and have a bit of a chat. He says there was one particular engineer, a genius when it comes to structural rigidity and so he rocked up at his office one day.

“I showed up and he said, ‘what the hell are you doing here?’ He had never seen a designer before and he was not used to it and he didn’t want to talk in the beginning, because he was fine doing his job and I was seriously getting on his nerves. He said all he had to do is focus on making the structure stable enough. I said yes, but we want to make your work completely visible.

The design team were fascinated with the Segway scooter at the time, but Langer admits that even though they were fun, people don’t look good on a Segway and they wanted their customers to look and feel cool

”If what you do is super nice and aesthetically 100% then we want to show it, no designer needs to cover it with anything. Then he got it for the first time in his life and some of the stuff that you see in an i3 is so authentic that it’s just the raw building of the car. It looks cool.”

There were other collaborative efforts too, such as the kink in the belt line. Initially it was a straight line, but Langer and his colleagues sat in the back and felt uncomfortable as though they were caged in behind a high wall. They found inspiration in architecture, where windows are placed to ensure occupants can’t see the neighbour’s wall, instead seeing a nice view and enjoying the light filtering in.

“That’s the logic we took as an inspiration and we said the belt line needs to be cut deeper in the back to give you a better feel. Now if you sit in an i3, you feel way more comfortable and the rear seats have more light and we’ve made it more roomy for people sitting in the back. That’s the reason for the kink, we had to come up with a design solution and it became iconic for the i3.”

The coach doors were also a purpose-driven design solution. Research suggested the car would mostly be used by occupants in the front seats, but the i3 team didn’t want owners to have to fold a seat forward to let people access the back seats. Early solutions created what Langer calls half a door, which wasn’t practical, so again the design team worked with the engineers to create the coach doors with integrated B-pillars.

There were challenges with the wheels too. Like most designers, the team wanted big wheels, but engineering said they wouldn’t be lightweight or aerodynamic enough. The design team were fascinated with the Segway scooter at the time, but Langer admits that even though they were fun, people don’t look good on a Segway and they wanted their customers to look and feel cool.

The engineers came back with a solution, big wheels that are narrow. Then they wanted more aerodynamics, while other engineers wanted better brake cooling.

The i3 created a whole new way of working, a new mindset when it came to the cars that being created

“They were all were coming to us, aerodynamics here and brake cooling guys there. I said you know what guys, please talk to each other first, get your stuff solved and whatever is the output we can deal with it.” he says. “The wheel process was a process of its own, but we learned a lot from it. We learned how important the efficiency is when it comes to aerodynamics and what a wheel could do. We gained a lot of knowledge out of these processes that are still valid and have become common sense within BMW.”

The same could be said of another part of the i3, the interior. Because occupants are physically surrounded by the design and interact with it, Langer says it’s much harder to do than the exterior, something we suspect many designers will agree with.

He is particularly proud of the way the instrument panel and HVAC system were integrated. Going to electric meant not needing a central tunnel and this allowed Langer and his team to completely rethink their approach and then hope that engineering would go along with it. Initially the response was not great, with engineering pointing out that it would require a completely new crash beam, re-engineered air tunnels and much more. Design stood their ground, again saying they wanted to make a feature of something, in this case the freed-up space.

“That’s the reason why you have that little wave in the middle of the dashboard and a free-floating lever where the CID was put on,” he says. “It had never been seen before, no other car had it because they couldn’t free that space up. Here there was a complete rethinking of the structure of the interior.” It’s this element that is Langer’s favourite within the i3, in part for its design but also because of what he and his team had to go through to make it work. He says it’s a key part of an interior that is still very different and which has not only aged well but still looks modern, even today over a decade after the car was launched.

That completely new approach to the interior is also apparent in the seats, which the design team initially felt were too thick and compromised the interior space they were aiming for. They won that battle too, the seats in the i3 being thinner than any on the market at the time while also retaining the essential structural rigidity for safety.

“We questioned a lot of things like this,” he says. “People were surprised how roomy that interior felt when they were inside and this is something they wanted to have in every car. It’s something we still offer because if you look in a BMW iX it’s designed the same way, more premium but the same kind of well-being roominess and comfort. The logic behind it is exactly the same.”

Speaking of new models, Langer is adamant that the i3 continues to influence the latest models. This includes directly related concepts like the i Vision Circular, but also the i4, a car which he says was always planned for those who found the i3 a bit too radical. However, it goes beyond just the cars he says, with the i3 creating a whole new way of working, a new mindset when it comes to the cars that are being created.

It broke the design mould completely and laid a foundation not just for BMW i but for the future of electrification

“The culture and the mindset we have today is based on what we developed back then for the i3,” he says. “When it comes to efficiency, the reason for doing things, sustainability, it all started back then and we developed what BMW i is today. Back then we had to discuss with people about how important sustainability is for cars. Today, there’s no question, I don’t even have to discuss it.”

We couldn’t let the i3 go without spending a bit of time with an i3S to get a personal reminder of what made it so unique. The world of electric cars has changed significantly over the last ten years and today we are used to driving more advanced EVs from Audi, BMW, Mercedes, Polestar and Volkswagen, not to mention a plethora of new brands.

The ride is firm, the driving range limited and it doesn’t charge with the high number of volts of many rivals. It wasn’t up to the challenge of a couple of long-distance trips, but it was never meant for this, at least not regularly, it’s an urban EV and when you see it as such, it’s simply brilliant. It accommodates four with ease, the coach doors are easy to use and are still a great talking point and it has all the tech most of us really need.

It’s impossible not to stand and look at it and when you climb inside, you can’t help but admire the raw materials Langer talks of, the elegant curves, practical features and of course the use of materials than many rivals are only now starting to consider.

Sure, modern electric BMWs are better technologically, but they aren’t a match for the character of the i3, nor the way it paved the road to electric. It broke the design mould completely and laid a foundation not just for BMW i but for the future of electrification.