Exclusive interview: design director at GM California Advanced Design Brian Smith

Design director at GM California Advanced Design Brian Smith speaks to Car Design News about his new role, design homogeneity, aero design and more

With stints at multiple brands within the portfolio, including Chevrolet and Cadillac, Brian Smith is a true General Motors man. Appointed design director of advanced design at GM California, Smith is tasked with forging new frontiers within design across GM, applying his knowledge to brand specific and broader boundary-pushing work. Recently, Smith worked on the Celestiq and Lyriq – a brace of landmark projects for GM that herald a new electrified era. However, you can trace his track record in experimental design all the way back to the GM Precept, which launched at the turn of century. Car Design News caught up with Smith to hear his thoughts on his new role.

Car Design News: With Cadillac being the boundary-pushing brand in the GM portfolio, how much of a natural step was it for you to move into advanced design?

Brian Smith: Within GM we refer to Cadillac as the tip of the spear. Well, Advanced Design is the tip of the tip of the spear. I was involved with all the EVs that were developed for the first generation of the EV portfolio: from Celestiq through Lyriq and others that will be revealed soon.

CDN: It is early days, but how do you see the role developing?

BS: What is interesting is the breadth of what you get to be involved with. I did some interior work early in my career, but I’ve been an exterior designer most of my career. It’s nice to be able to look at the vehicles holistically from the inside out and not just the exteriors. It’s a great team. Frank Saucedo built a pretty good organisation there over 22 years.

CDN: How big is your team?

BS: Right now, about 20 designers. We have some engineers on site, as well as a shop where we can build prototypes. We have a very strong digital team and a team that does digital visualisation.

The California studio has done well at finding new technologies, new programmes and new software so that we can better demonstrate our products virtually and review them virtually. They pioneered HMD years ago using head-mounted displays and now that technology is in all the studios here in Warren. Being close to tech in California is a big part of what we do – to try to really marry those technologies to not only what we do but how we do it.

Sometimes a concept bubbles up that you find a brand for after the fact

CDN: How do you guard against the kind of homogeneity that can come with tech?

BS: It is hard to make a big flat screen from pillar-to-pillar all the way across an instrument panel look different from any other. Once you have got a giant screen, what’s next? And I think the Innerspace, the Cadillac that the California studio did just recently, is a great example of where interior design can go and how you can merge that autonomous technology with an experience inside the vehicle that is very different from vehicles today. The next big part of the future is how do we deal with autonomous vehicles? And how do we keep engaging the customer and not create an appliance that you sit in and go from point A to point B?

CDN: You mentioned digital tools – are clay modelling skills now secondary in the design process?

BS: While we can do things purely virtually, nothing beats a full-size clay model. The team in North Hollywood, from a clay aspect, is very talented and very experienced. And so I’m leveraging that. I fully believe in hand sculpted surfaces. I think digital can get you pretty far but that last bit that adds the absolute beauty in the surface – I feel like it has to be done by hand.

But I like to work back and forth. I think there’s opportunities for the digital team to stay engaged through the whole process. And I’m trying to emphasise having every aspect of the team be part of the creative process, not just designers. I want the digital team to be creative. I want the sculpting team to be creative. I think the best products always come out of that intense creative collaboration.

CDN: And how does the work break down – are there brand-specific projects?

BS: I have been meeting with the executive directors here talking about next projects and what they’d like us to dig into for each of their brands in the next year. But there will be some amount of unbranded work as well. Sometimes a concept bubbles up that you find a brand for after the fact. And then we’ll modify it as needed to fit that brand. We are exploring look and feel and how we influence the proportions and surfacing of some of the brand work.

We are adding the California West Coast influence to everything we do

CDN: How do you see the relationship developing with the European studio?

BS: We haven’t gotten into specifics of how the workload is going to be broken up yet, but I think they’re going to be much like us. We are adding the California West Coast influence to everything we do. I think Julian will be doing some of the same things but taking the European approach and finding those influences. And one of the great things about having a centre in Europe is we could bring in European talent.

CDN: What’s the reaction been like to the Celestiq? It has got a fairly hefty price tag attached to it.

BS: It is a stunning vehicle and a lot of the cost of that car is just in how it’s built, right? It’s built slowly with unique processes and by hand in a lot of cases, so that costs a lot of money when you slow the process down like that and you’re only building a couple a day. But I don’t think we’ll have any trouble selling them – we are not going to make that many. I think we’re going to learn a lot from manufacturing and technology standpoint from that car. I know we are trying out some new things there, which will end up trickling down into other vehicles.

CDN: What about the idea of more design-led manufacturing. What potential do technologies like 3D printing have to reshape traditional Fordian methods?

BS: The challenge is a lot of those new processes like 3D printing or Flexfab is that they are not particularly fast. They save you having to tool anything and you can make shapes that previously you couldn’t make any other way. But right now, it’s slow.

So, I think it’s finding the right ways to scale that. But you can imagine how quickly then you can change whatever it is you’re building just with software and be spitting parts out instantaneously for something else you just designed. The possibilities are really exciting.

How do you find ways to do an expressive design that still gets the numbers?

CDN: We are seeing a re-embracement of aero design to increase battery range. How we see exterior design language evolving in this kind of era over the next few years?

BS: We are seeing a lot of different brands taking different approaches to aero. And now that we have these kinds of flat batteries on the undersides of vehicles, there’s more opportunity to make a slicker shape. Our engineering team is developing some pretty advanced tools to predict aerodynamics and we’re going to get involved with how we design for aero.

CDN: The perennial challenge is to make sure all the cars don’t look the same?

BS: Right, so how do you find ways to do an expressive design that still gets the numbers? And that’s a big challenge. You have still got to package people in there and it’s the combination of frontal area and CD that is going to become more and more ingrained in the original shape than it has been in the past.

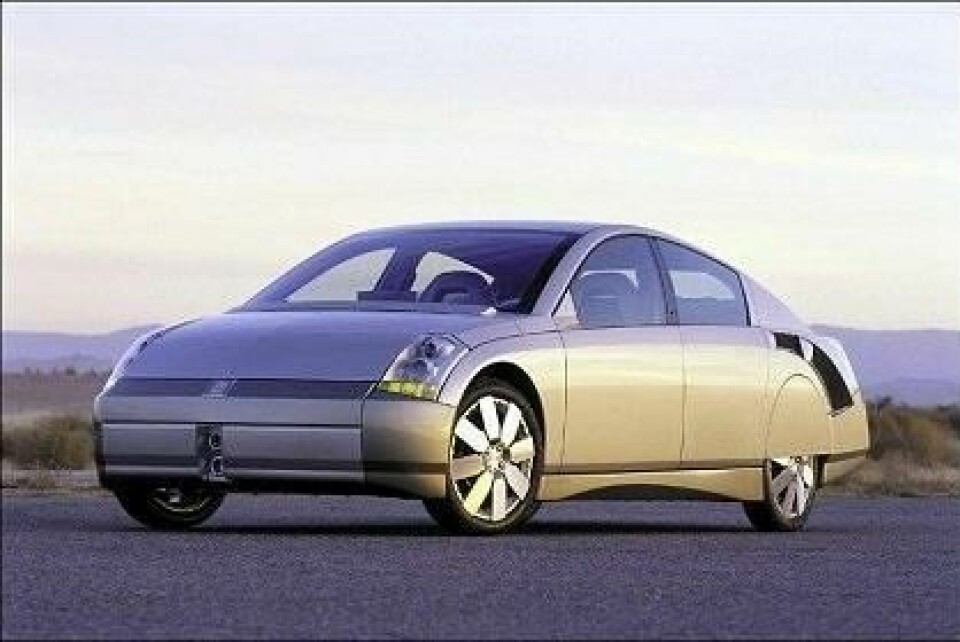

We have typically created a design and then tried to improve the aero versus looking at it holistically from the beginning. I’m excited to get into it. I worked years ago on the GMP program back in ’98, ’99 where we did a five-passenger sedan – GM Precept, which had a .162 CD. It was a pretty wild looking car – aero is near and dear to me because of that vehicle and I think there’s a lot of opportunity there.