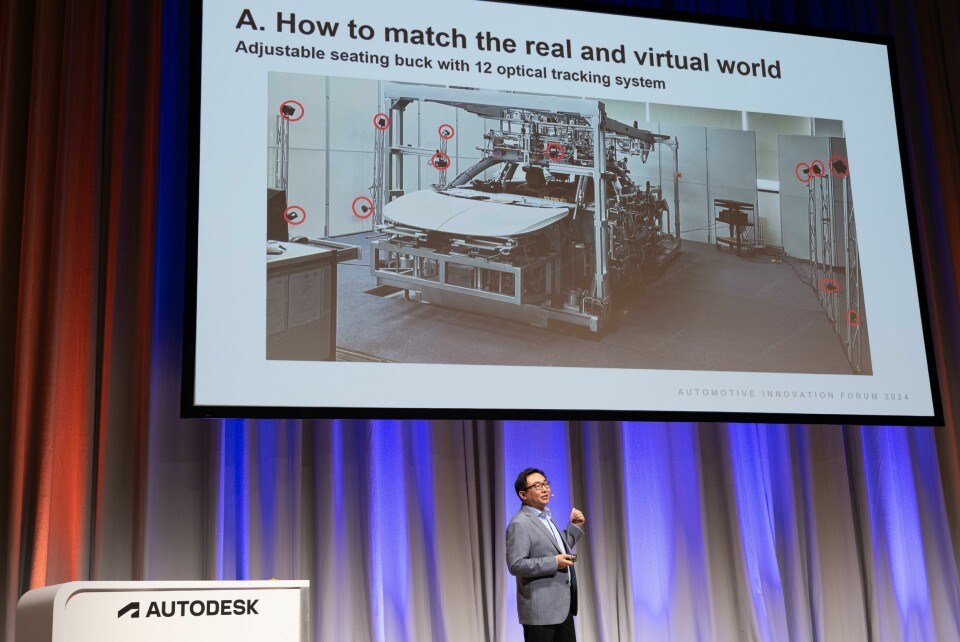

FAW-VW on the future of VR in car design

Car Design News sits down with Han Luqiang, a virtual reality engineer at FAW-Volkswagen, to see how VR is helping the team

Han Luqiang has been working with virtual reality (VR) for the best part of a decade. Plenty has changed during that time and what once served as a nifty toy has now become an key tool in the designer’s toolbox.

Speaking to Car Design News during the Autodesk AIF conference in Darmstadt, he discussed his role as a VR engineer at FAW-Volkswagen, the evolution of VR from a hardware perspective and what’s coming next.

Car Design News: You’re fresh off the stage from your presentation at this year’s AIF. How did it go and what’s the event been like?

Han Luqiang: I like it very much. It’s a chance to see a lot of different automotive companies from around the world and to see their work. It’s important to share knowledge between us all, and to understand what other people are doing. Without these kind of conversations we cannot progress.

CDN: In terms of your presence personally, you bring a level of expertise in virtual reality. Could you give me an idea of what you do as a VR engineer, and how VR helps the design process?

HL: I think my time could be split into three parts. The first is preparing visualisation data and in VRED in order to prepare for VR reviews. The second part around the use of the hardware, advising on how to use it and what the highlights and the disadvantages might be.

Today, we have a much bigger field of view and the situation has totally changed

CDN: Yes, I suppose it is both a physical and a digital tool with that headset on.

HL: Right. It almost looks like one of those old school bubbles that people wear on their head at a hairdresser. In a way I could almost say that I have indirectly touched so many different peoples’ heads across the company. The third part of my job is to be almost like a scientist, doing research into the technology, scouting new functions to try, if new hardware of software can connect with VR to create new solutions. There is a lot going on.

CDN: How long have you been working with VR?

HL: About seven years as a VR engineer, but before that I was using AR technology for almost two years.

CDN: I’ve heard how quickly this technology is evolving, so I imagine it’s very different to when you first started using it?

HL: When I first entered this field, the best use case of VR was based on big powerwall and a complex CAVE system. There were projectors behind the screen and you could wear 3D glasses which to be honest gave a very good experience early on. But they had two problems: one is that it was too expensive for such an immersive system, maybe around US$1m all in. The other was that they required a lot of space and could be hard to maintain. But the high-mounted display (HMD) glasses we are using now are much cheaper and we can even get better results.

There are two benefits: money and speed

Seven years ago, several companies’ first-generation streaming products allowed you to play games. At that time, the quality, the resolution of the HMD, was not very good. In other cases, the field of view was very small so it was hard to see scenes clearly. Today, we have a much bigger field of view and the situation has totally changed.

CDN: In what way?

HL: Some of the latest VR products today support 4k resolution, for example, and the field of view is more than 100 degrees – much better than when I first got into the field. Over the last seven years, we have gone through five generations of HMD technology, so we are changing to another headset almost every 18 months.

CDN: So the costs of using VR have come down, but at the same time, the usefulness, usability and accuracy has improved. Could you talk to me about the use of VR in the studio – what are the benefits for a design team using VR compared to one that doesn’t?

HL: There are obviously two benefits. One is money and one is speed. For example, if we wanted to make some decisions without VR technology in the past, we had to make a physical prototype. That is expensive and might take one or two months before the design leader can make a decision. But with VR technology, we could provide the opportunity to make decisions very, very quickly without those costs.

CDN: Should every design studio be using VR?

HL: Yes. It’s a key tool in the toolbox.

CDN: If we look five, ten years out, what do you think will have changed – what’s your vision of the future of VR?

HL: In my imagination, the headset will become lighter and lighter. Some weigh about a kilogram which can be a lot over the course of the day. The framerate should also improve: a very good frame per second means we can get more of a realistic experience of light, reflection and things like that. Maybe the equipment manufacturers will provide more powerful products. And perhaps further out we will be able to experience something that is really like the real world, which is not yet the case today.

Today the UI/UX designer can provide a prototype of the HMI without writing any formal code

CDN: We’ll have to see. I didn’t realise how heavy the headsets are – that’s like having a bag of sugar strapped to your head…

HL: Yes, you do need to take some rest periods at the moment.

CDN: Part of your presentation today was how VR can be used during the development process for an HMI system. Could you give us a bit more on that?

HL: In the past, basically every element of the user experience had a single physical button to control it. But today, new cars feel very clean and there are far fewer buttons. This means the way we interact with the car is totally changing. We talk to it, we touch the screen to find controls, but if it is not well designed the user will suffer.

We think that the HMI needs to be tested far more at the very early design stage. For example, right now the UI or UX designer can provide a prototype of the HMI without writing any formal code. That prototype could give an idea of the position and the logic of the menu, and we can perform lots of different checks before moving forward.

CDN: So this again comes back to making things quicker and easier. You can see what works, see what doesn’t, and iterate quicker than before.

HL: Exactly. With initial designs we will surely find a few problems that need addressing. If we can solve all of those problems using VR before they write code, that will save a lot of time and effort.