CMF teams target closer collaboration with engineering

Below are the key takeaways from CDN’s recent livestream: how will CMF shape an electric future?

The automotive design world is undergoing huge universal change with new ways to reshape the exterior and interior of cars. CMF teams sit at the heart of these changes.

To dig into this increasingly significant field of design, we recently gathered experts from Ultrafabrics, Lotus and Lucid to discuss themes such as customer education, the relationship with engineering departments, how location can impact colour palette, and of course, sustainability. But as we learned, there is no single approach to CMF, with strategies varying by OEM customer, region and end user. One thing is clear: the shift to EV does present an opportunity to shake things up and, crucially, push the boundaries.

Speaking during a recent livestream hosted by CDN and supported by Ultrafabrics, the panellists began by addressing the ‘C’ in that acronym. It is difficult to generalise how colour trends are changing within the automotive space as it is influenced by so many different factors – price range, brand story, expectations around durability or premium feel – and it is even harder to settle on a particular theme given the disparity between trends in fashion or home interiors (which changes almost monthly) and automotive (which typically has a two-three year lead time).

“Automotive is very different to any other industry. We are more about being timeless, so if the trend of the month is ‘purple’ that won’t necessarily work for us,” says Marie-Camille Lecoq, head of CMF & sustainability at Lotus. “We are of course aware of trends going on in fashion and interiors, and how we can incorporate them in the car, but it is more about looking at what is happening with technology and materials rather than with fashion. It is super interesting and always digest that, but it is not quite the same in automotive.”

There’s something beautiful about using colour as an accent

Jennifer Hendren, senior director, product development at Ultrafabrics recognises that the ‘scandi’ aesthetic is a prevalent trend at the moment when it comes to car interiors, but suggests that the introduction of colour does not necessarily need to result in bright, brash colour palettes.

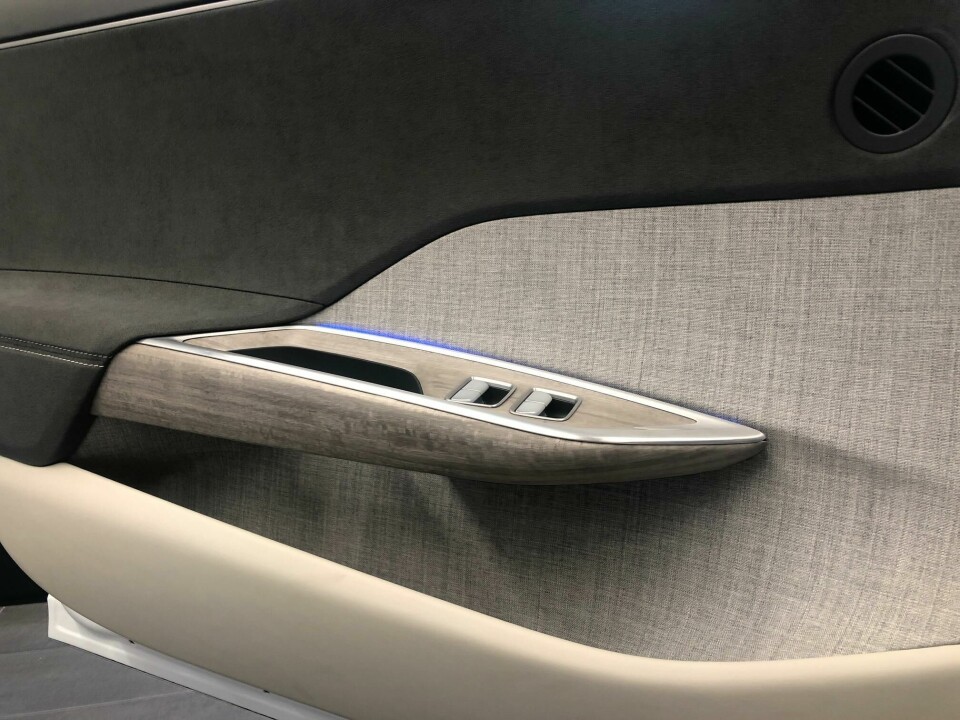

“We are known as a colour destination at Ultrafabrics, but for different markets there are different approaches to how colour is used,” Hendren says. “A lot of what we sell in automotive is light colours fading into greys and blacks, but we do see colour used in specific places rather than across an entire car interior. In other industries like healthcare, you might add a red or green to define the shape of a chair, for example. There’s something beautiful about that use of colour and we can certainly talk about using colour as an accent.”

Nicola Danks, colour & materials design manager at Lucid, suggests that inspiration can be taken from nature and, where viable, taking cues from the studio’s roots. “Colour is incredibly important for Lucid, and our CMF is partly designed around the different locations and times of day in California,” Danks explains. “There are vibrant colours in nature but muted colours too. We also link our us of colour to the mid-century movement of California, so there are colours and themes you don’t want to disassociate from.” Lucid also has a front to rear split when it comes to colour, which Danks says “evokes a different kind of feeling depending on where you sit in the car.”

I think we are moving to a point where materials are probably the priority

At Lotus, there is perhaps a greater emphasis on the ‘M’ in CMF. Colour is still important as it generally shapes the mood of the cabin, but as Lecoq explains, materials do not necessarily have to be refinished for the sake of it. “As CMF designers we love colour and are sensitive with it, but I think we are moving to a point where materials are probably the priority,” Lecoq says. “It’s still really important to take care of colours, but if a material looks a certain way we shouldn’t need to add a chemical to alter it. It is the way it is and can be expressed in a different way. Colour is obviously something I love, but materials are really driving the direction for me.”

Indeed, it is not only about natural materials but also natural dyes and pigments. These do not always age in the same way, meaning finishes could fade or perhaps vary more from vehicle to vehicle. Customers – both OEMs and end users – should be educated on that, Hendren says. “We do also see a real interest in this area. Those dyes don’t have the same longevity and consistency because they are natural, but there’s a beauty in the inconsistency and the natural aspect of those dyes. For example, if you want a coffee dye, there won’t be a the same kind of consistency as a conventional dye, but isn’t there a beauty in that?”

We have this legacy where cars have to look like they did on day one

Just like the patina on a vintage watch or the cracks in a well-loved leather arm chair, the interior of the future might be built around materials and finishes that wear naturally with age. This is not what drivers are typically used to – ‘old’ cars get replaced after a few years for partly that reason, they want it to feel fresh for as long as possible – and there will need to be some education around that.

“It really depends on the customer rather than the brand,” says Danks. “We have to educate our customers on why there is a patina, explain that it hasn’t been faked and it’s just how the material adapts over time. We have this kind of legacy where cars have to look like they did on day one as it is a high ticket item. So we have to find this balance – withstanding numerous trials and retain some sort of newness, but educating customers on why materials may not look perfect.”

Education, education, education. This was a key theme that ran throughout the livestream and as moderator and CDN editor James McLachlan pointed out, this suggests a level of responsibility not only on the producer but the consumer to make sustainable choices when it comes to CMF. “People want to feel good about the things they buy. We have to explain where those products are coming from and let them make that determination themselves,” remarked Hendren. “As long as we as a company are being critical about what we choose to put out there, it is up to the customer whether that becomes part of their story.”

Lightweighting is a real challenge and CMF can help with that

CMF decisions can also have an impact on an engineering level, particularly so with EVs which are generally more sensitive to additional weight. They already carry around grand pianos in the floor (larger battery packs are incredibly heavy) and so even small gains on the lightweighting front are crucial.

“We may we have to embrace different ways of combining the A and B surfaces, exposing them and recognising the beauty in that,” says Lecoq. “We have been stuck for many years with the same basic approach, but new processes that are becoming available allow us to be more creative and expose parts that people haven’t noticed before in order to save weight. Lightweighting is a real challenge and CMF can help with that.”

With that in mind, is the relationship between CMF and engineering evolving? Lecoq certainly thinks so and not only with the internal teams of the OEM but also with their major suppliers. “It takes a team to come up with the best solutions,” she affirms. “At the start there might be some difficult conversations, but I think everyone is moving in the same direction now. Engineers are passionate and love to discuss this with the CMF team. It makes my job super interesting as it is more technical and opens new doors.”

From bonkers ideas, you create magic

Ultrafabrics’ Henden agrees, noting that “the idea of silos is very old school” and that “cross functional conversations lead companies forward – it’s the only way to push the boundaries.” Over at Lucid, collaborative workshops are run between CMF and engineering divisions to assess materials, manufacturing, cost and complexity. Suppliers play an important role here as they generally have a better idea of what their product can do. “

Lucid: “We work hand in hand with our engineers and then we involve our Tier suppliers. You can’t innovate in a silo, you have to open the doors to everyone else,” Danks explains. “Yes it can take some time and some of the ideas are bonkers, but from bonkers you create magic.”