Interior Focus: Trim & Materials

We take a look at the new materials, textiles and techniques enabling greater experimentation and creativity in the automotive sector

New materials, textiles and techniques are enabling greater experimentation and creativity in the automotive sector, driven by design curiosity, a genuine desire for development, and changing consumer tastes and demands, particularly with regard to sustainability. Attention is being paid to both raw materials and end-of-life recycling – with some quite startling sources for new textiles and fabrics making their industrial debuts.

Fabrics from food waste

The seats of Volkswagen’s ID Roomzz concept, revealed at the Shanghai show in April, feature a textile called AppleSkin that incorporates left-over residues from apple juice production. In the Volkswagen application, fruit waste replaces 20 percent of polyurethane (PU) content but AppleSkin’s German developers, Nuuwaï, have a 50 percent blend in production for fashion items such as handbags and backpacks.

The material is made by drying apple waste, grinding it to a powder, mixing it with PU, and then applying the result to a cotton backing. Washing and heat treatment stages impart flexibility and weather resistance, and the surface can be embossed much like tanned leather to give a decorative finish.

Technical fabrics already used in sportswear and fashion continue the fruitbowl theme. Bananatex has been developed by Swiss firm Qwstion into a hard-wearing waterproof weave with 100 percent banana-tree fibre content, coated with natural beeswax. It has been used to create a range of bags and backpacks. Italy’s Orange Fiber makes a silk-like cellulose yarn from citrus waste, featured in recent capsule collections for H&M and Salvatore Ferragamo.

Ananas Anam’s Piñatex, a leather substitute made from pineapple leaf fibres, has also been used for bags and shoes. For the Paris motor show last year, Piñatex was mixed into a carbon twill weave for the floormats of the Skoda Vision RS. The material was also used to trim the seats of a lightweight prototype racer called the Thyssenkrupp blue.cruiser, a World Solar Car Challenge competitor built by students at the University of Bochum.

A line of sneakers from German footwear firm Nat-2 has even found a use for waste milk. The main constituent protein of milk, casein, was first extracted to make textiles in the 1930s. Today, a modern process developed by start-up Qmilk extracts the protein and mixes it with wool fibres to create a felt. The company says two million litres of milk are thrown away each year in Germany alone.

Nat-2, meanwhile, is also marketing ‘vegan’ shoes with fibres from sources including coffee, hay, grass, fungi and flowers.

The challenge of extracting usable fibres from waste products – in an energy-efficient and cost-effective way – may be getting easier, too. Finnish start-up Spinnova, winner of a 2019 World Changing Ideas award from business magazine Fast Company, has patented a solvent-free mechanical process to spin yarns from wood pulp, agricultural waste such as straw stubble and other cellulose fibres, said to use 99 percent less water than cotton production. It has been collaborating with Finnish textile company Marimekko.

Bio-blended composites

Bio-blended composite materials are moving beyond the conceptual stage, while manufacturers of leather alternatives are working to reduce dependence on petroleum-based polyurethanes and similar plastics.

“We would love to go to 100 percent but have to keep in mind industry regulations and specifications,” says Christine Diaz, global design director for transportation at Ultrafabrics, outlining the difficulty of moving to entirely plant-based materials. “There are challenges for durability and water repellence, for example, so we need to get the right ratios, with each product manufactured uniquely, to maintain the performance.”

Ultrafabrics plans to launch a new bio-based textile this autumn. “We’re moving forward on recycled content in terms of textile backing and looking to develop and incorporate more plant-based resins,” Diaz adds.

Pioneering production examples include the door and dashboard panels in BMW’s i3, supplied by Dräxlmaier, moulded from a bio-composite that combines natural fibres from the kenaf plant with polypropylene (PP). According to Dräxlmaier the mixed material can deliver weight savings of 20 to 50 percent compared with plastics alone and, once coated with a thin PP film, offers colour options, UV stability and scratch resistance comparable to conventional alternatives. The fibres are deliberately made visible in the i3 to underscore its eco credentials.

One of the trim options offered with the latest Range Rover Evoque features Tencel, a plant-based textile made with eucalyptus wood fibres, stitched alongside artificial leather from Ultrafabrics, made with recycled polyurethane.

Meanwhile, BX microfibre material from Ultrasuede, launched in January 2019, features around 30 percent plant-based content derived from waste sugar-cane molasses and castor oil.

Substitutes for petroleum-based products are currently making in-roads into the sportswear industry. Dutch swimwear and watersports clothing brand Wallien, for example, is using an oil-free ‘limestone neoprene’ constructed from polymerised calcium carbonate.

Repurposing plastics

Repurposed plastics are now a strong theme for many brands, including Audi. The German marque’s Q4 etron concept, shown in Geneva this year, and etron GT from last year’s Los Angeles show, both featured recycled flooring material, as did the AI:ME at the recent Shanghai show. The AI:ME’s surprisingly soft and sumptuous carpet used an Econyl yarn made of recovered fishing nets – “a very nice narrative” according to colour, trim and materials coordinator Annamaria Palmigiano. “It’s related to tech advancement, a rising sense of ethical respect and commitment to sustainability,” she adds.

This kind of sentiment fits well with general consumer trends. Fashion brand Ecoalf has established ‘Upcycling the Ocean’ projects in Spain and Thailand to gather discarded plastic items from harbours and the sea. The collected waste is cleaned, processed into flakes, then spun into polyester fibres used in a wide range of clothing, in which the source material is very much a selling point.

“We’re sourcing materials with a story behind them: the fibres, the ingredients, the manufacturing processes,” says Ultrafabrics’ Christine Diaz. “Consumers are becoming more conscious. It’s a big move in automotive and designers are really trying to push the message and make changes.”

Last year, Volvo built a demo version of its XC60 plug-in hybrid, showcasing its aim to incorporate at least 25 percent recycled plastics by 2025. The specially trimmed SUV featured a tunnel console with fibres from discarded maritime ropes and nets; recycled plastic bottles yielded the PET-blend seat textiles; and carpets used recycled PET fibres as well as waste cotton from the garment industry.

“We do need increased availability of recycled plastics if we are to make our ambition a reality,” noted Volvo’s Martina Buchhauser, senior vice president of global procurement, at the car’s unveiling last summer. “That is why we call on even more suppliers and new partners to join us in investing in recycled plastics and to help us realise our ambition.”

Where thermoplastic polyurethane (TPU) is needed or most appropriate, it should also be recyclable at end-of-life – and not just into lower-grade products. Sportswear brand Adidas is developing a circular-manufacturing range for retail release in spring/summer 2021 called Futurecraft. Loop. Sneakers made from a 100 percent recyclable TPU yarn are moulded and fused with midsoles of the same material, meaning that no glue is used and no disassembly is needed when worn-out shoes are recycled into new yarn.

The fabric upholstery in BMW’s i3 is “virtually 100% recycled polyester”, according to the company, while one of the Range Rover Evoque’s trim options pairs Kvadrat woollen textiles with a recycled suedecloth from Dinamica that is said to contain around 53 half-litre recycled plastic bottles per car.

Fiat also notes the importance of eco-friendly production. It chose 100 percent recycled yarns for the sportswear-style technical 3D knit used for the seat-backs of its Concept Centoventi, shown in Geneva this year. The mesh seat backs were made in a process where fabric of varying cross-section can be created, reducing waste and leftover materials.

Softer smart surfaces

Integrating controls and displays into hard surfaces is becoming more common. The touch and gesture sensors in the Audi AI:ME concept, for example, are set within a Corian composite for a warm touch, while the production-issue Geely Geometry A sedan, launched at the Shanghai show in April, features backlit touch-sensitive buttons embedded in the surface of its centre console.

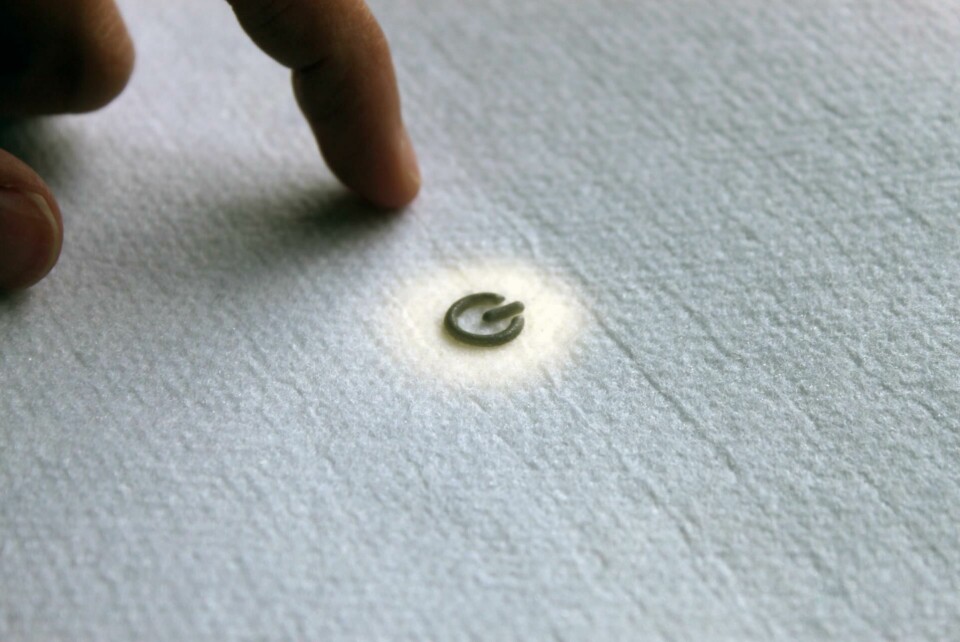

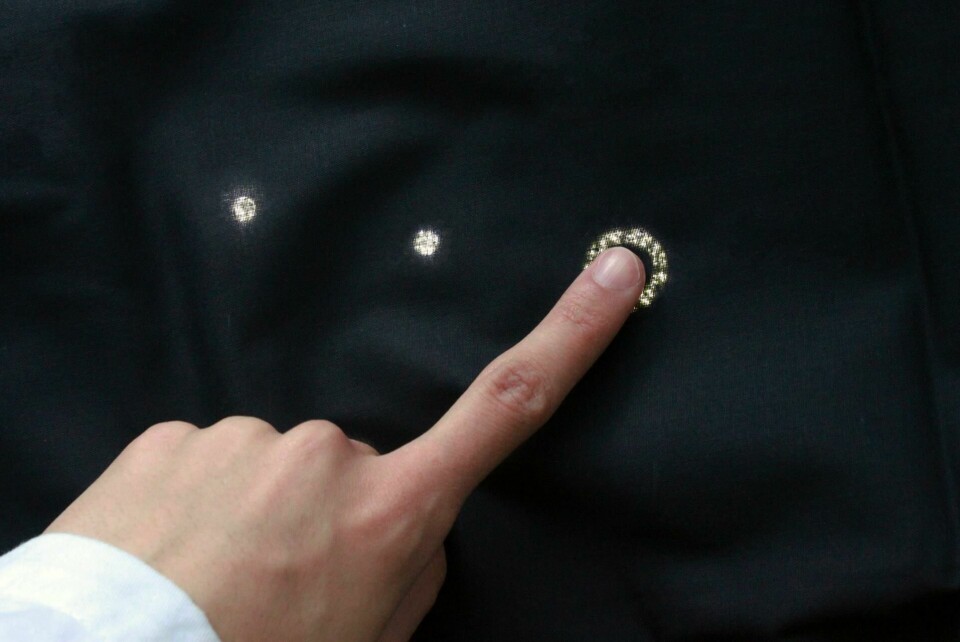

Incorporating controls within textiles is perhaps further off production feasibility, but the Italdesign DaVinci revealed in Geneva earlier this year – a luxury GT concept dedicated to Leonardo, no less – illustrated the potential. It featured backlit control icons, for various features including cabin temperature, glowing from beneath smooth stretches of Alcantara applied to the dashboard and the rear part of the centre tunnel.

New York-based start-up Loomia has developed a modular, customisable, backlit control option called LEL (Loomia Electronic Layer), which can be supplied as a panel to be sewn, bonded or glued to a textile surface, within a client’s supply chain and production processes. The soft control can then interconnect with a car’s electronic systems in the normal fashion. “The soft, flexible and drapeable form factor breaks the design limitations on control surfaces or other electronic elements in a car interior,” says Loomia chief product officer Ezgi Ucar.

“The technology is versatile enough to be designed to do anything a circuit board can do,” she adds: “Soft control surfaces, sensor and output mechanisms in the seats and steering wheel, and passenger comfort applications including soft heating, ambient flat lighting and vibration outputs.” Ucar explains that the base textile is a conductive mesh, insulated by a soft thermoplastic polyurethane (TPU) film: “It feels light and smooth, with a very thin profile. We can change the insulation for our customers’ needs as well as customise the colour and feel.”

Prototype seating created for aircraft manufacturer Airbus by London design studio Layer explores how smarter materials might help to make economy-class flights more comfortable [6-9]. The seating concept, called Move, designed by Layer’s Benjamin Hubert, features a ‘digitally knitted’ textile with conductive threads linked to sensors for monitoring factors such as temperature, pressure, movement and seat tension. Each seat can be remotely configured by the airline but also links to a bespoke app, downloaded by the occupant, for personalised adjustment. Layer says Move’s adaptability, compact foam-free format and lightweight aluminium and carbon structure promises significant benefits. It would be easy to imagine similar seats in the context of a shared mobility vehicle.

Clerkenwell Design Week 2019: forecasts for colours, tones, moods and textures

The Interiors Trend Report 2019/20 from analyst firm WGSN and sourcing platform Eporta was presented in May, during Clerkenwell Design Week, outlining four themes:

• ‘Bilingual interiors’ fuse inspirations and complementary craft techniques from different global cultures. Under this umbrella come sub-trends such as ‘sugared Scandi’, where minimal forms are highlighted by soft pastels – mint, dusky pinks, neutrals, soft blues – and stronger yet soothing earthy natural tones.

• ‘Energy reboot’ brings playful, child-like colour schemes, reflective, refractive rainbows, iridescent, translucent surfaces and optical illusions; and ‘recharged wellness’ is about light, tactile and natural materials, homeliness and relaxation: wool is important, and apparently the lumpy, loopy look of bouclé is back.

• ‘History lessons’ embraces handcrafts such as weaving, hand-tufted textures and imperfect, maybe mismatched artisan products, plus 1970s-style ‘retro brights’ in terms of colours and fabrics.

• ‘Elements’ combine fire – rough flame-like effects, burnished, tarnished and oxidised metals, with yellow and ochre shades; air, symbolised by sky-blues and “dark galactic” space-inspired colours, crystal and mirrored surfaces; earth, with natural materials such as cork and plywood; and water, with ocean-inspired tones, pearl, shell motifs, turquoise and coral. Aqua blue is a key shade for 2021.

Phil Pond of trend agency Scarlet Opus described a number of similar themes in his presentation at Ultrafabrics’ London showroom, describing two main trends looking ahead over the next three to five years.

• ‘Imperfect beauty’ celebrates authenticity, salvage, restoration and repair. This trend features natural tones such as raw umber, clays and greys, light and mid-tones set against rustic touches such as raw untreated woods. Soft-look leathers are also part of the theme, as are crackled, distressed and charred wood finishes. Another aspect is the contrast of rough textures meeting smooth, or graceful forms meeting brutal or industrial shapes.

• ‘Satori’ encapsulates an ongoing Asian influence. Pond cited Japan’s cultural traditions, history and craft techniques, serenity and balance, and space, light and quiet. Textures are inspired by the raked dry surfaces of a zen garden, and Asian motifs such as a flying crane, fans and deco-style scallops, and even the famous Hokusai ‘wave’ design all reflect the theme.

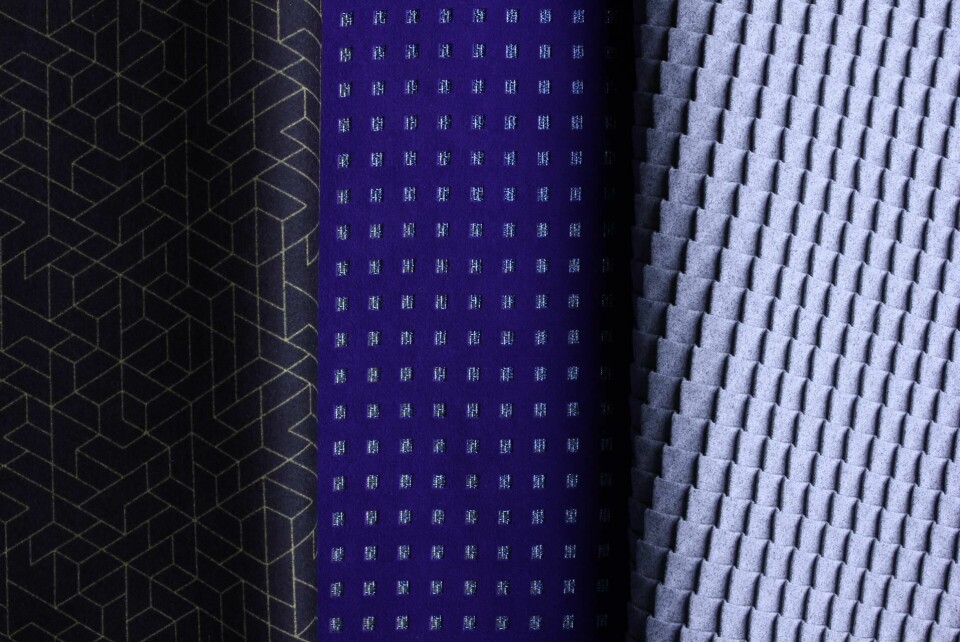

Blue notably dominated the Kvadrat showroom in Clerkenwell, following on from the textile brand’s ‘Blue is Divine’ tribute at Milan Design Week, celebrating designer Finn Sködt and his favourite ultramarine. Pond adds that indigo blue will become “the new black” in four to five years.

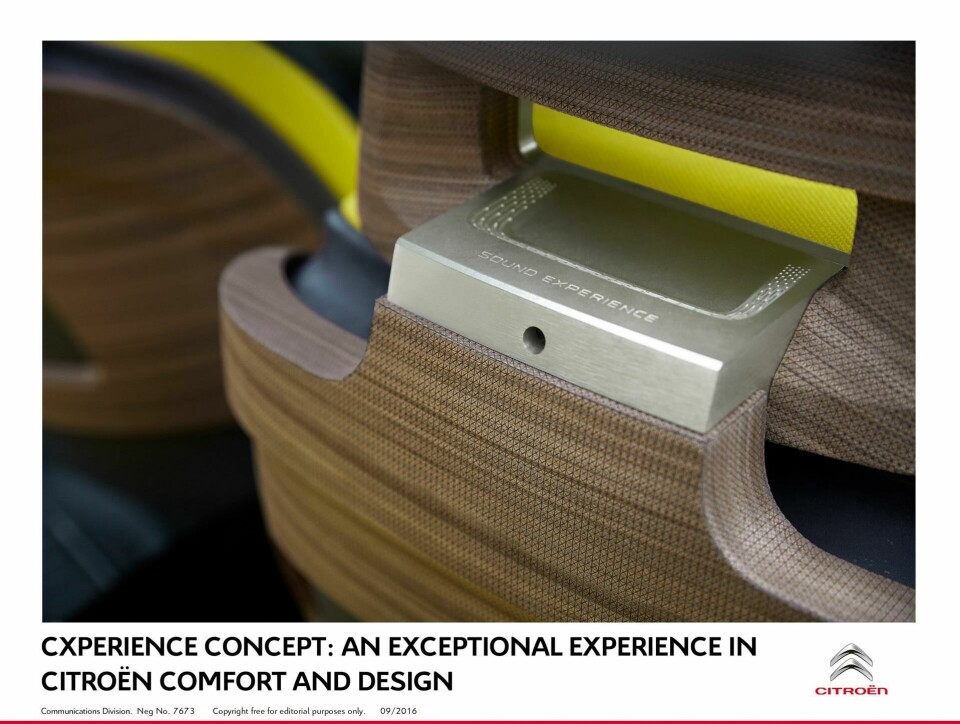

Technologies and techniques

New production processes and digital techniques are opening up fresh possibilities, unlocking new materials as well as reinvigorating more familiar choices. Volkswagen’s I.D. Roomzz featured wood fabric from Ligneah (similar to that seen in 2016’s Citroën CXperience) where laser-cut veneer is bonded to a textile backing. The technique enables wood to be applied and used in new ways.

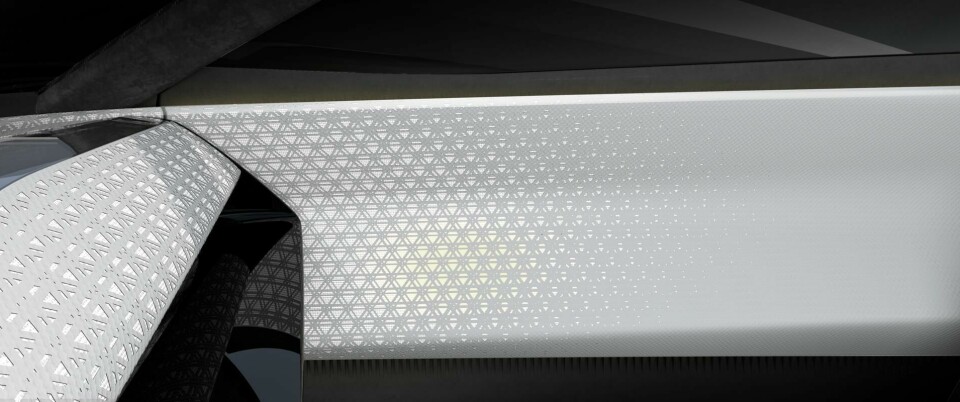

Similarly, Nissan’s IMQ concept, seen at this year’s Geneva motor show, had its 3D technical fabric laser-cut in geometric, Japanese woodwork-inspired patterns.

Digital printing is being deployed by Miko on its Dinamica microfibre. “It gives designers the freedom to print images onto the seat or other parts of the car, adding colours or patterns directly to the suede,” explains marketing and design manager Benedetta Terraneo. “This is a very precise way to translate an image or colours.” Miko is now using lasers to cut perforations and etch surface textures, and can electro-weld to create zig-zag or pleated surfaces without stitching.

This all brings new possibilities for individualisation – and even DIY. “We’ve used traditional luxury materials for so long, and the customer is changing – in a totally different space, thinking about different technologies, expecting something different,” says Marek Reichman, chief creative officer at Aston Martin Lagonda. “We’re still using wood, but in different places, but also 3D printing, sintering, with other new materials – there are far more opportunities for personalisation, even in your own home. That’s the trend: you can design and print your own substrate, you don’t have to rely on the factory.” These ideas were expressed in the Lagonda All-Terrain concept shown in Geneva this year. The approach could become widespread, with Fiat exploring the notion of home-printed accessories for its Concept Centoventi at the same show.

3D printing also provides an option for low production runs and one-offs. Citroën’s Ami One Concept, shown in Geneva this year, used powder-coated plastics for its flooring, and its counterpoint, the 19_19 long-distance autonomous cruiser (seen at the VivaTech show in Paris in May) had a digitally-developed 3D mesh fabric applied, in various colours, throughout its lounge-like cabin.

A new term – nanospinning – is used by outdoor brand The North Face for its ventilated Futurelight fabric, which features nano-level holes through which air can pass. The new material is due for launch in late 2019 and is suitable for outer-layer jackets, gloves and even tents. BMW calls it “the world’s most advanced, breathable, waterproof material”. BMW’s Designworks team stretched the new fabric across a domed framework for its Futurelight concept camping trailer, shown at CES in Las Vegas earlier this year. The result evoked memories of 2008’s GINA concept, which similarly blurred boundaries between interior and exterior materials.