First Sight: BAC Mono R

Updated single-seater cleans things up and sets a path for the next generation – air scoop and all

Talking to CDN from a pristine new design studio in BAC’s ‘innovation centre’ next to its factory in Speke, Liverpool, co-founder and design director Ian Briggs reflected: “I don’t want to sound too grand, but our dream would be that the Mono becomes like a 911, in that it evolves over time – and I’m sure that, over time, it might broaden its appeal, however we decide to do that. There are all kinds of things you could do, so I hope that the ‘bloodline’ of Mono will iterate over the years as we go on, to better focus it on the different customers, who go touring the Alps in it, or who only use it on the track.”

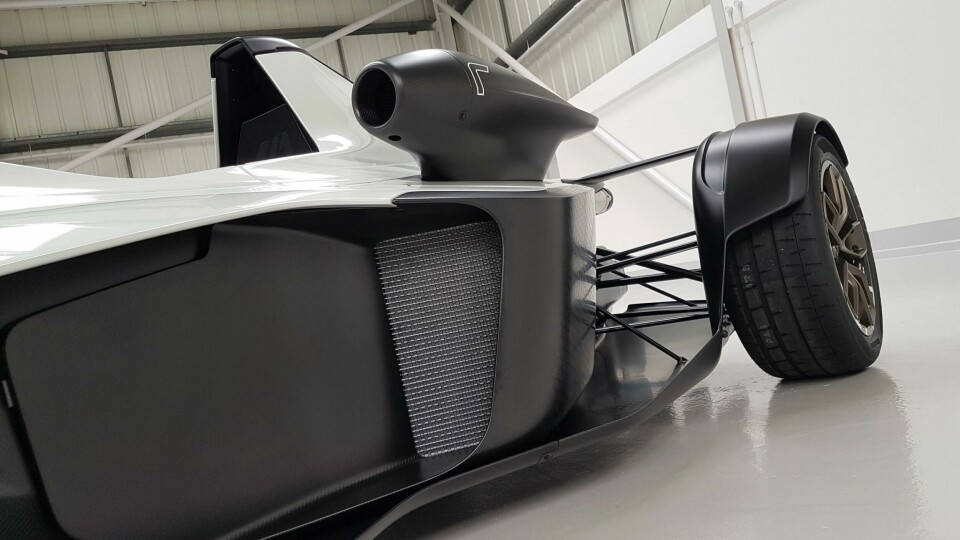

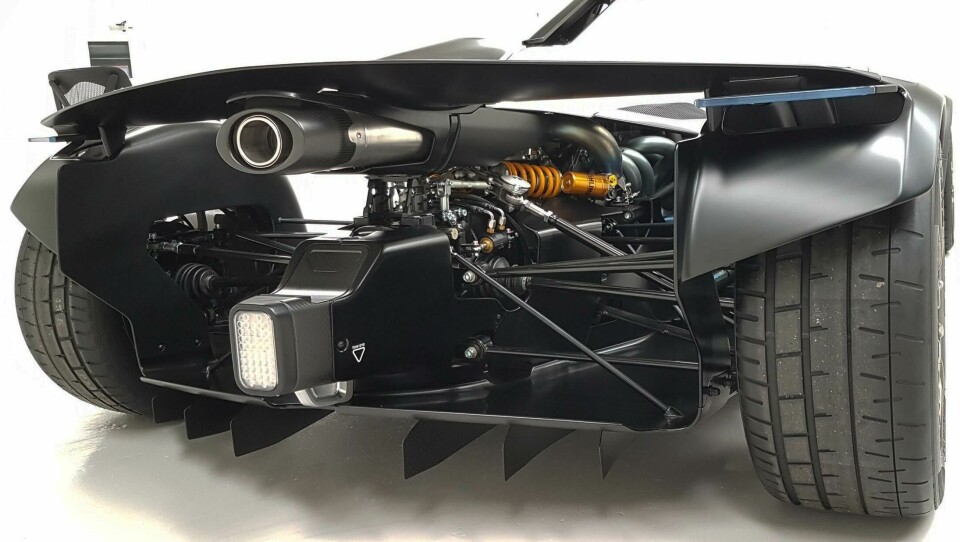

Certainly, the standard BAC Mono doesn’t look like it’s already eight years old – perhaps because in all that time, it arguably remains unimitated. The only visually comparable cars we can think of are the Roboracer and the new Formula E car, neither of which are road legal. Originally taking inspiration from motorcycle fairings and the robots in Björk’s All is Full of Love music video, it remains a fascinating object to take in detail by detail, its two-tone livery separating the softer, aesthetically-driven ‘upper body’ and the purely technical ‘lower body’ as it teases and later reveals the mechanicals beneath while you walk from front to back.

Up until now, the single-seater’s evolution has all taken place underneath its wafer-thin two-tone skin, with updates to the engine and chassis hardware solidifying its reputation amongst track-day enthusiasts and lightweight fanatics. With this new ‘R’ model, however, BAC’s team of five designers, including design director Ian Briggs, and senior designers Guy Harvey and Murray Adams, were able to give the Mono a full aesthetic evolution for the first time, in an intensive ten-month project – but not without a fresh wave of mechanical updates being added in tandem, as this limited run of 30 cars bridges a gap between the Mono we know and a next-gen car that we’ll see in the near future.

“We did the clay model for the current car in summer 2008, so we’ve always looked at it for years since then thinking ‘I just want to move this and tweak that…’ so I wouldn’t say that everything we’ve done here is just for the function, but it all starts with a function,” explains Briggs, adding “I’m hoping it won’t just be engineering updates again for the next ten years!”

If there is one 911 parallel to note with the Mono R, it’s that an untrained eye might look over the body and think that (prominent air intake aside) it all looks “the same” as the Mono we’ve seen since 2011 – only to be told that every single panel has been redesigned. Then you look closer and start spotting details like the new lights – starting with the peculiar central element tucked under the prow (where the front registration plate used to go), which constitutes the ‘main beam’ headlights.

“It was a bit of an ‘ah ha’ moment for us,” Briggs said of discovering that there are no regulations specific to the positioning of main-beam elements. “There’s a little bit, but it doesn’t give you anything about the height or distance from the outside of the car like all the other lighting.” Thus, they could take one pair of the light units out of the cavity between the front wheels and integrate it onto the central main body. “It reduces the frontal area of an element that would otherwise have been in the wind.”

It’s the effect of this change in particular that Briggs is most satisfied with. “The purity and cleanliness of that front view, maybe from a bit closer so the front light starts to disappear; there’s no other car in the world that’s as clean as that at the front.”

Moving back from the new nose, new, longer two-arm mirror mounts sit behind the exposed pushrod suspension. Further down, the area behind the front wheels has been opened up to excavate air from the arches. “This is an area that I thought always tended to look a bit heavy on the existing car,” admitted Briggs, “so in this area, we have these blades, the inner and outer blade, and when you stand at the rear ¾, you can see the tyre through there. It gives us lots of visual lightness. I don’t think this line [at the wheel arch’s trailing edge] has significantly changed as a line, in side view, from the current car – but because all this mass has been removed it suddenly changes that whole area aesthetically.”

“The visual tale that we’re telling through the car is that everything’s just become 50% of what it was before – and that visual lightness is something which for us is appropriate to a car that’s as physically light as this and as optimised for lightness as this – so we want the form language to speak that.”

The elements surrounding the cockpit area have also been altered to tweak the proportions and tidy-up certain elements. The black suede area in front of the short vertical aero screen is longer, while the leading edge of the upper structure, around the driver’s head, has been pulled forward and radiused to subtly wrap around an imagined racing helmet. This all aims to make the Mono R look a little more cab-forward.

Outboard of the cockpit, the sidepods – initially created by tucking the body in to make it easier to climb in and out – have also been reworked to accommodate bigger radiators, as Briggs explained. “This generation of the car will form the next generation of Mono, so while this is Mono R, in the future there will be a regular Mono which will replace the standard car, and it most likely will be forced induction in some form, and we needed more capacity in the radiators for intercoolers, things like that – but even for Mono R itself, with 343 horsepower, it needed more cooling.”

This did present a problem in the ‘visual lightness’ department, though, which the team resolved carefully. “Visually we didn’t want to upset the balance in terms of width, so the extra we’ve added is this black outer section, and then the side surface is more vertical. We’ve also got moulded intake ducts, sealed to the radiators, so the capacity we’ve got is not only bigger but it’s being used more efficiently as well.”

Underneath the tightly stretched carbonfibre skin, the Mono’s main structure (still based around a tubular spaceframe instead of a carbon tub, to control costs) is such that if you were to remove the bodywork and axles, what remains would have a plan view akin to that of a kayak. With the R, BAC aimed to lengthen and narrow the ends of this central inner form – which was achieved partly through the necessity of improving safety.

“There’s a version of this gearbox used in Formula 3 cars that uses a crash structure – we’ve always had a crash structure at the front, but never at the rear – so as we’ve added a crash structure to the rear, it’s allowed us to extend the tail,” explained Briggs. “Plus, if you recall, it had two square lights down here in the past, which was more than double the width of this.”

“As this has come back and got narrower, we’ve pulled the wing back and we’ve adjusted the plan shape of the diffuser, so this whole area is getting cleaner. The taillights below the wing have now gone into the silhouette behind the wheel, so we’ve reduced frontal area and visually cleaned up the rear end as well.”

The attention to design details goes as deep as replacing a longitudinal shutline where the wing joins to the rear wheel arches, with a lateral one – effectively making the wing itself a slightly wider part. “The whole point of this join is that your eye really understands the width of the vehicle, because obviously it’s unusual that the front looks wider and it ends up quite narrow, so it’s important that your eye still sees it as having four wheels and not a being three-wheeler.”

The interior is little different from before, save for the side panels now being in exposed carbonfibre, rather than upholstered with the same weatherproof suede used for the rest of the driving environment as before – a material that was quite a find for BAC. “In the end I was fed up with going on to fabric companies all the time about what we need, and getting ‘what, a single-seater?’ and ‘has it got a door?’ and all that,” commented Briggs. “I said, ‘listen: I want a fabric for a motorbike seat. It’s going to get wet, it’s going to get sun, someone’s going to slide all over it, yeah? That’s what it’s got to withstand.’ And this is what we ended up with.”

The chosen material solution has somewhat humble origins. “Clarkson always liked to make fun of this on TopGear; it was originally made for hospitals and care homes – this fabric is designed so that blood, and all the horrible things that come out of human beings, can go on here. It’s got a silver oxide on it to stop bacteria growing, it’s got a waterproof membrane behind it so that any moisture doesn’t go through to the foam – it’s been an absolute wonder material for us.” The central seat base, by contrast, is in a special waterproof leather from Boxmark – better for standing on, as is necessary in a car with no doors.

The section of suede that reaches forward from the aero screen is there not just to visually lengthen the cockpit and balance the proportions, but to eliminate sun glare for the driver and provide them a non-slip surface for putting the steering wheel during ingress and egress. Said wheel is now a fully carbonfibre unit (with 3D-printed CFRP shift paddles), reshaped to make it easier to carry when detached and more ergonomic to perform tight manoeuvres with while driving.

Of course, there is a bare-carbon elephant in this clean white room: that air intake. Followers of motorsport will recognise this prominent missile-like setup from Formula 3 cars. Briggs explained that “it gives you the cleanest path for the air, straight into the engine. On the old car, the air came in over the driver’s head and had quite a convoluted path into the engine. It works, but we found that if we just ran an open induction system on the side, we were gaining horsepower. We’re getting six-to-eight horsepower at full speed from the ram-air effect.”

Because the Mono R runs an inline-four engine mounted longitudinally, it only needs this on one side (the exhaust manifold is visible from above through a grille on the other side). If you ask us, the fact that they didn’t add a dummy “bazooka” on the other side for symmetry’s sake, as suggested by internet experts, only adds to how purposeful it looks.

“From a design point of view, some customers want to see it look more integrated into the body, essentially asking if it could be in body colour,” Briggs elaborated. “The reason we chose to do it like this for the show car is that it’s part of the engine that’s sticking out, and so I don’t want it to be evaluated as part of this upper body. I want it to be seen as a technical element.”

Moving the induction system away from the roll hoop also allowed BAC’s designers to slim-down the top point of the car – deleting the CHMSL in the process as it was “having a hard time” sitting above the hottest part of the car, especially in hot climates.

“The area behind the driver’s head is about 25mm lower, but the structure below it that’s protecting you in a crash has not changed, so it’s no less safe,” Briggs clarified. “On the old car, we had this ‘spine’, and on top of the spine you had the main body, and on top of that you had a removable panel to access the engine… so you had a stack-up of all these elements. We’ve changed that whole area so that everything’s fitting much more closely to the structure now, which again has reduced the frontal area.”

This push to slim down or merge components is evident all around the car, from the aforementioned lighting to the machined towing eyes integrated low and centrally at each end, as well as carbon bodywork made with graphene-infused resin to allow a 10-20% weight saving on all the panels. Details like these are what make the Mono R feel like an evolution, smarter and more efficient in its design than the original.

Briggs suggests that the Mono concept will have plenty of scope to evolve further, and will have a clear role to play in the future. “I think this product will become easier and easier to understand as transport becomes less about driving and more about moving people around in autonomous vehicles. Then, when a car’s got a steering wheel it’s because someone wants to drive, they want to control the machine, and then it doesn’t have to have any of those transport requirements.”

“It’s a car that you use in the same way as skis or snowboards or balancing bikes – you know, nobody goes to work on their skis, and no-one would compromise their skis with luggage capacity, and no-one says it’s selfish being a skier because you can’t take anyone on them with you. So, the way people use sport equipment, is the way we see this product being used.”