The Volvo team unpacks the EX90

The team behind Volvo’s flagship EX90 offer their unique perspectives on the design development of the car

Any design director worth their salt will tell you that a successful project is the result of good collaboration, not just within the design departments but across related areas of the business. With that in mind, Car Design News asked the Volvo team behind the flagship EX90 to talk about their role in the project.

Car Design News: What was the key to a successful collaboration between design and engineering?

Maria Järdhult: With an all-new electrical platform there were many challenges, everyone had things they wanted this car to achieve with a good opportunity for innovation on a new platform. We listened to understand what each department wanted to achieve to find a perfect balance without compromising design; the key is to come together and ensure we work towards same goal.

Before joining the Volvo design team, I worked outside of design in the core engineering teams. Joining design as a studio engineer has given my day a lot more variety (and challenges!).

From the very first sketch we work hard to protect the selected design through development phase, to be able to retain the emotion and feeling in the design

Sometimes I feel like an interpreter between our designers and the wider engineering teams. I understand what the designers are looking for, at the same time I understand the engineering in depth so I work to challenge and optimize the sections to translate this vision to a reality with quality.

Reviewing physical prototypes and clay models together provide common understanding and it’s a great visual tool to discuss the opportunities forward.

One thing that I am particularly proud of is the endless engagement of the team, how everybody comes together especially at the end of the process before our final release to create something we can all be proud of

I particularly like working on the small details, they are concentrated in shape design and require such a precision in execution, how they fit together and how to achieve such precision in manufacturing processes with the size of cutters, print nozzels and to meet the tolerances we expect without shinkage of materials,

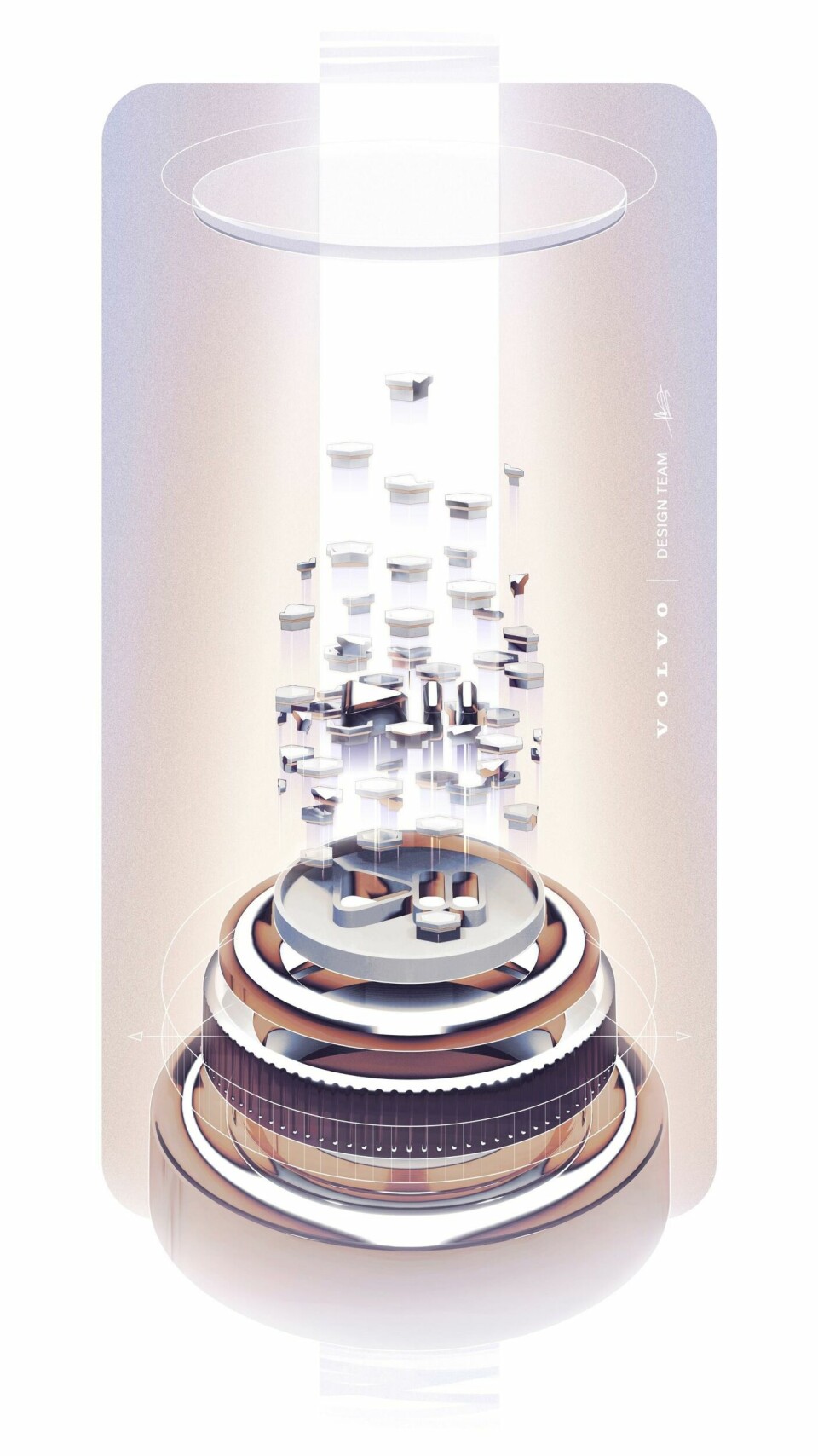

The attention is in the detail. We analyse tenths of mm – the customer would probably not notice but we do, which is how we achieve the premium brand quality The vent wedding ring was one of my favourite details, the three pieces interlock together like a puzzle.

This is the first time we have used 3D printing in a customer facing element and we learnt a lot from this process

Also the audio rotary 3D printed centre – the precision in the shape and depth of the pattern and how to work to get the light coming up through the pattern evenly was a a challenge. This is the first time we have used 3D printing in a customer facing element and we learnt a lot from this process.

One thing that I am particularly proud of is the endless engagement of the team, how everybody comes together especially at the end of the process before our final release to create something perfect that we can all be proud of. The strength of the team, trust and dependance on each other grows through the project and the sense of achievement together at the end can be overwhelming.

CDN: How did you ensure a human-centred design with the IP?

Guglielmo Guiglia: When designing the EX90, we made sure to prioritise a human-centered approach in order to create a space that meets the needs of both the driver and passengers. The lower IP is designed with a concave and clean shape in order to provide maximum roominess for the occupants, creating space for personal items to improve the experience.

Controls, audio system, cameras inside the car are integrated in the volumes to give the less distraction and maximum comfort. The architecture is designed to emphasise the UI which provides the right information at the right time, to provide a natural and effortless user experience.

The natural deco has a sophisticated shape as it supports the central screen and spans the width of the cabin connecting the driver and passenger. in the night time the natural wood glows up with a pattern from behind, expressing the pure Scandinavian experience where nature and light mix interacting.

The warm coloured glow creates a sense of warmth inside and positive wellbeing, just like it does when the sun shines in Sweden and lifts your mood after a dark winter. We learn how to celebrate the use of light in the cosy dark evenings to compensate for lack of day light.

Designing the interior was important to us to have same precision, treatment of surface, proportions for all the front row and all the interior to create a environment consistent in form language and human interaction

The balance between soft surfaces and constructive feature lines is creating a feeling of richness, and a psychological safety , the precision of the construction and the different materials that help define the shape are giving a crafted premium feeling and feel great to the touch. All senses are considered in our designs.

The clean sophisticated volumes are celebrating the detailed jewelry, details like the air-vent controls, we called “wedding rings” through their development because of their round ring like shape with the detailed jewel on the end are designed to be a precious interaction between the user and the Volvo EX90.

I really enjoyed working on the wedding ring control and especially proud after all the iterations and models to see it look so great in the way it enhances the design of the car.

In designing the interior it was important to us to have same precision, treatment of surface, proportions for all the front row and all the interior to create a environment consistent in form language and human interaction.

Using new materials as we developed the design have given us the opportunity to create a more sustainable cabin.

Car Design News: How did your creative background lend itself to this project?

Camilla Ernvid: I love to work with my hands, My background is a seamstress, and I still make dresses for myself in my spare time! There are some similarities between making clothes and dressing a seat, working with 3D forms and templates but a seat is much more challenging.

It is always a challenge to achieve a precise tailored and tight fitting design working with soft materials in the early phase, so it takes a lot of trials with our new materials to achieve the desired impression. Its really important to me that the materials are soft and supple, with a little bit of flex but not too much, to behave in a good way to be shaped and to hold its shape.

I find the variety of projects really exciting. While working in isolation on small elements it is really satisfying to see it come together as one vision in the interior bucks, the compilation, how the different elements complement each other and create a beautiful harmony.

We start by milling out the seat foam from cad data of the designed shape that has been developed with comfort sections, we draw and lay out the templates, and all the pieces of materials and details to include in the sewing towards the final assembly of the seat.

Trimming work is a hand craft, involving a lot of trial and error. You really focus closely on the detail in the process to get the best quality you can every time

Trimming work is a hand craft, involving a lot of trial and error. You really focus closely on the detail in the process to get the best quality you can every time. It takes a lot of skill and, as it’s a hand worked process, you can get hung up on any slight imperfections throughout the day.

However, you come in the next day and you go “Wow! That actually looks great!” it is great to stand back with fresh eyes and absorb the big picture. We learn from every trial we do and improve to get the fit perfect, we also learn a lot from each other throughout the day, each trimmer has their own specialities so we help each other out to achieve a great design!

I work very closely with the colour and material and interior designers to interpret their designs into reality. We all have our own perspective on how something should be made so I will bring my own experience to work together to interpret their design vision.

Car Design News: How did you work with the wider design team to ensure a harmonious relationship between the interior design and UX

Anna Arasa: When people think about User Experience they tend to talk about what can be found on the screens.

What it should be is really a holistic view of the experience while owning and using the car, inside and out, analysisng every touchpoint and how it makes you feel through the experience.

We do a lot of testing to validate how we design: with ergonomics, testing and interacting with driving functions, and making prototype models to evaluate the materials touch and feel and lighting experience.

The contextual bar is a great example of where the car will provide the right information at the right time, for example when you arrive at a parking destination, the pay function automatically pops up for you to start parking in the app

The aim is for a calm space with a warm ambience, integrating technology to provide a simplified natural experience where the customer does not feel outsmarted by the car, rather understood and supported for an effortless experience.

The contextual bar is a great example of where the car will provide the right information at the right time, for example when you arrive at a parking destination, the pay function automatically pops up for you to start parking in the app. A connected experience where the User interface is constantly updated over time and provides new features as they become available.

We work together with the Interior, exterior and colour and material design teams on elements like buttons, lids and physical spaces to design an amazing User Experience inside and around Volvo Cars.

Car Design News: What was the key challenge with the exterior lighting design. What were you trying to achieve?

Marcus Nilsson: In a visually busy environment our T-bar head lamp signature of our current cars stands out from the competition.

For the EX90 our ambition was to push this concept to the next level.

We wanted the contour – the main periphery around the lamp — to be as slim as possible so the T-shape headlight could be most clearly readable, day and night.

This had to be achieved without sacrificing class-leading light performance, where the high beam requires the strength of two additional larger light modules.

In the concept phase we built Lego models to understand the package, movements and to communicate our ambition

While designing the light package we need to understand in parallel the space we had to work with for the exterior proportions in the front end. We were also looking for something more. But it could not be just a gimmick, form needs to follow function.

Many different possibilities were investigated by our team, we came up with the idea to position the main beam modules behind the hammer, and now the focus was how to move away the horizontal hammer from in front of the modules.

In the concept phase we built Lego models to understand the package, movements and to communicate our ambition. Besides helping us to see trough “different glasses”, Lego also talks to the playful side of ourselves. It definitely was my favourite toy as a kid, and it still is even I seldom get the time these days. But it directly became clear that I shared the love for Lego with most of the engineers in the team.

The solution that was chosen was to split the horizontal hammer in an upper and lower part and move them up and down like eyelids! Besides solving our geometrical problems it gave us the “Easter egg” we had been looking for. It gave the car more personality to the front face and we loved how it emphazised a human expression and created an emotional connection.

We added complexity with the moving parts in order to achieve a simplistic and pure hammer expression

It was such an exciting experience, for the first time, to see the movements of this special design through prototyping. And it is very satisfying to see the result in the production lamp and to see the reactions of wonder and amazed faces as new audiences see the car for the first time. The welcome sequence consists not only of animated LED light and projections but also of the mechanical moving hammer to open the eyes, the car is winking at you as you approach.

I like to work with the big picture and then work with all the details and see how it all comes together. There is a lot to consider when designing a front lamp, in this project we added complexity with the moving parts in order to achieve a simplistic and pure hammer expression. We worked with different problems everyday and that made every day unique and exciting. I feel very privileged being part of this incredible dedicated and creative team that made this lamp come to life.