CMF insights from Alpine

“My team is very free to explore” – Stephanie Petit, CMF head at Alpine

Car Design News speaks to Stephanie Petit about sustainable materials, 3D-printed finishes, and French craftsmanship – from leather traceability to illuminated triangles

At Alpine, the colour and trim team is steering the brand into new creative and sustainable territory, with a focus on innovation, performance, and French savoir-faire. That’s according to CMF head Stephanie Petit whose strategy is a convergence of cutting-edge technology and artisanal detail.

“In terms of strategy… we want to have some innovation,” Petit explains. “Based on the pillars that we have — lightness, performance and French savoir-faire.” That savoir-faire translates to intricate embellishments and elevated detailing, which Petit pushes her team to explore. “I want to push my team to work on many details and embellishments to have something very high level positioning.”

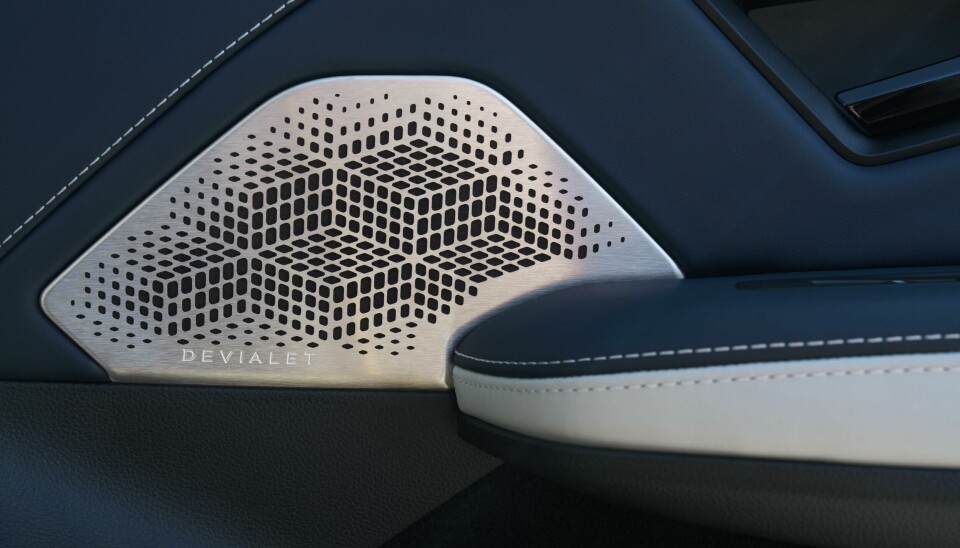

This vision is materialising in Alpine’s use of 3D-printed metal and aluminium elements and bespoke finishes that go beyond prototyping into production-ready components. “We start with prototyping for sure, but we transform [it] to have that in a real car,” Petit says.

Design motifs, such as the triangular pattern, now appear throughout the new A390 — from the light signature to perforated leather seats and translucent microcovers. “We consider that the triangle is one part of the identity of the brand,” Petit notes. “We wanted to use that with perforation, with gradation on the seat… with small triangles [and] a backlight with the other textile that we use.”

Working across departments is key to Alpine’s creative cohesion. The CMF team is tightly integrated with both interior and exterior design units. “It’s like a startup,” Petit says. “We are really close all together with different design competencies… the interior designers, CMF designers and exterior designers are really, really close.”

The overlap of disciplines allows new technologies to flourish. “With 3D printing… you can design one shape and have at the same time the finish,” she explains. Materials like polyurethane (PU) are printed with patterns that create depth and lighting effects — a blend of CMF and product design in one move. “What you see on the lights, you can find it on the seats, on some patterns in the mould of a plastic or carbon part, for example. And I think we have this strength of consistency.”

Petit leads a tight team of eight, encouraging broad exploration before refining concepts. “I give them the target. They have to explore many things… and after that we focus on narrowing it down. But I let them be very free.”

On the use of leather, Alpine remains an exception within the Renault Group, which is moving away from the material. “We are the only brand still working leather in the Renault group,” Petit says. The brand sources nappa leather with a focus on sustainability: “The target we give to our supplier is to have traceability, small parts with small quantity of animals. Not too far from the plant… and to reduce chrome from the process. So we look to vegetable tanning — coffee or oil.”

In addition, Alpine is exploring partnerships with high-end furniture manufacturers like Poltrona Frau. “I’ve known them because I have some furniture from them,” Petit adds. “The exchange and the work with them is really interesting.”

Ultimately, Alpine’s CMF philosophy is about longevity. “We want our A110 and A390 to be collectable,” Petit says. That emphasis on enduring materials and consistent brand identity — down to the smallest triangle — is at the heart of Alpine’s evolving design DNA.