Car Design News spoke to Magna Exteriors experts Larry Erickson, Global Director of Exteriors Design Group, and Brian Krull, Global Director of Innovation – Exteriors, about the looming challenge of creating aesthetically pleasing autonomous vehicles.

CDN: Today’s experimental autonomous vehicles tend to feature a roof-rack full of ugly equipment. Will it be possible to better integrate the hardware as autonomous technology becomes more mature, to create more pleasing shapes?

Brian Krull: Roof-mounted modules provided a logical first step. Test vehicles tend to use sensors, such as rotating LiDARs, which will be replaced by more advanced components as LiDAR becomes a solid-state technology. You’ll have multiple smaller sensors that are lower-cost, integrated around the vehicle in different areas, providing the same capability as the sensors on the roof today. So, components will be integrated more seamlessly as part of the progression of sensor technology.

Larry Erickson: For the bulk of vehicles going down the road, integration will become seamless. Front and rear surface and graphics will evolve to accommodate the appropriate sensors, but the OEM design groups will find ways to refine those constraints to work with their brand identity. We may see some highly functional designs for rugged, off-road vehicles, but I think that the roof-rack of items is not something anyone wants to utilise over the long term.

CDN: What is Magna Exteriors doing to combine function and aesthetics for future autonomous cars?

Krull: When you look at Magna as a whole, we’re very well positioned to deal with future mobility, including autonomy. We take a full system approach to providing solutions for the car of the future, whatever that may be. We know future vehicles are going to include a vast array of sensors, many of which are offered by our electronics group, and from a design standpoint we have the task of integrating sensor technologies in an elegant way.

From my perspective, on the innovation side, it’s about the technologies we can employ to conceal sensors but still allow them to function, in a way that meets the needs of designers.

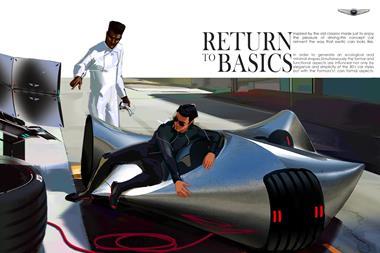

Magna’s MAX4 autonomous vehicle demonstrates possibilities for elegant integration of sensors

Erickson: From the customer point of view, there are different ways we can go. The sensors can be integrated so you can’t really see where they are, which in a lot of cases is the preferred approach. But we may also find that a recognisable sensor can be an attribute, similar to a driving lamp or a surface detail. It depends on how they’re integrated, and how early in the design process you start to consider options.

I think we could see a wide variety of approaches. Initially, it will be about just getting the task done, then as things settle people will start finding their own identity in how they integrate sensors.

CDN: What other innovations, beyond core autonomous capability, do you think might become important in the same timeframe?

Erickson: As new kinds of mobility are enabled by autonomous vehicles, there will be situations where we’ll want to monitor both the occupants and the vicinity around the vehicle. If you’re having your children picked up from school by an autonomous vehicle, you’ll want to make sure they get on board safely. You’ll want to do that under all conditions; poor weather or in low light, for example. So I think sensors will have a role beyond just making the vehicle operate. They can contribute to making the whole mobility system operate more effectively.

Krull: We’re looking at things like how we bring light through a surface, so we can use light to communicate not only with the user of a mobility service but with others including pedestrians or other vehicles, so that light becomes communicative. Plastics really enable those types of solutions, which is what we specialise in within Magna’s exteriors group.

The potential for exterior lighting will grow with autonomous vehicles

Erickson: Once autonomous vehicles get into different environments, lighting may be used in ways we haven’t anticipated. As the car is able to do more things for more people, and put itself in more situations, I think the potential for exterior lighting is going to grow.

CDN: What kind of challenges need to be overcome to seamlessly integrate sensors and displays in vehicle bodies?

Krull: We have to look at the limitations and constraints around sensors. The positioning of sensors around the vehicle will be driven by function, and different sensors have different requirements.

Radar can typically see through opaque and even painted plastic, but of course there are requirements in terms of the thickness of the panel. And as radars get smarter they may become more sensitive, so we could even be looking at the thickness of the paint. So there’s quite a bit around materials we have to understand, not only in materials but manufacturing processes as well.

Another question may be the need to remove ice or debris from a sensor surface, to maintain signal transmission through all the different environmental conditions.

Some sensors have to be perpendicular to the surface they’re transmitting through, which doesn’t necessarily lend itself to good external design, with curvature and 3D geometry. Our goal is to look at how we address that within Magna, through materials as well as sensor technologies, to achieve not only the function but also the form we’re looking for. The end goal is to ease restrictions for exterior surfaces.

Advanced materials considered upfront can enable greater design freedom

Erickson: These are questions you want to consider upfront and early to avoid ending up with that rack on the top of the car. With a change in material from steel to plastics and composites, you actually have more flexibility in some respects. You have more design freedom than with a metal panel.

So there are advantages and challenges that come out of this whole sequence. Working with a supplier that’s been manufacturing complex composite panels, for a great number of customers at high volumes, will be a key enabler in getting the most out of the materials and optimising the positioning of sensors.

You also want to start work early to make sure you’ve got the right capabilities across the whole system. That’s partly why we’ve been doing what we’ve done recently; to get out to the design community and open up lines of communication.